2-Pair STB Box

- Product Description

The terminal block of connection adapts for connecting the distributive wires of external and internal padding. Its construction provides the possibility of conducting the control measurements of the connected chains before both directions. Box provides protection from the environmental effects.

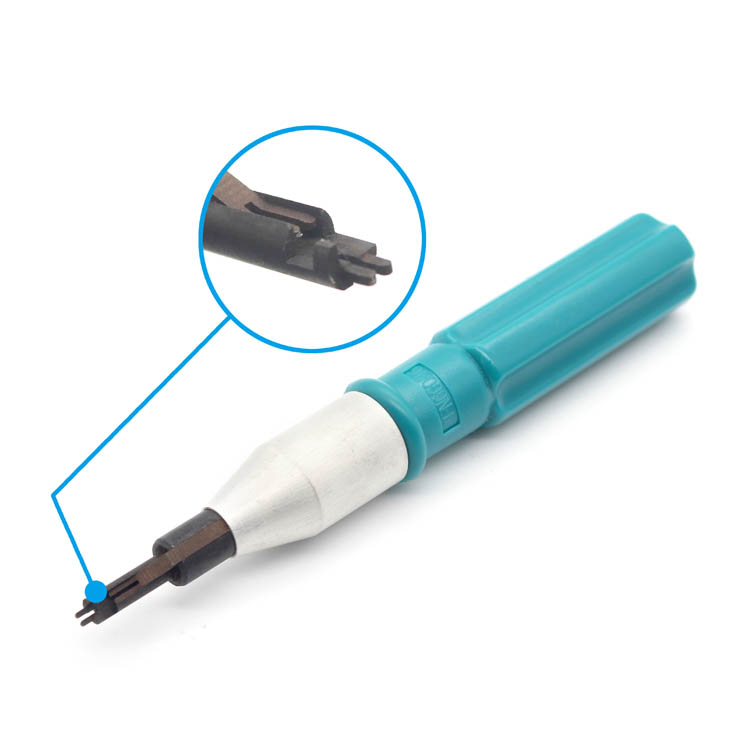

The terminal block of connection consists of housing and cover of rectangular form, and also 5- polar unit of connection, fixed on the housing. Cover is fixed beyond the axis common with the housing; however, it can be isolated from the housing for guaranteeing the convenience in the work due to the squeezed conditions. The introduction of wires is accomplished through the detachable stuffing boxes, which ensure the possibility of applying the wires of different sizes. Fastening wires is accomplished by the metallic screws, located inside the unit of connection.

| Products Specifications | |

| Contact characteristics | |

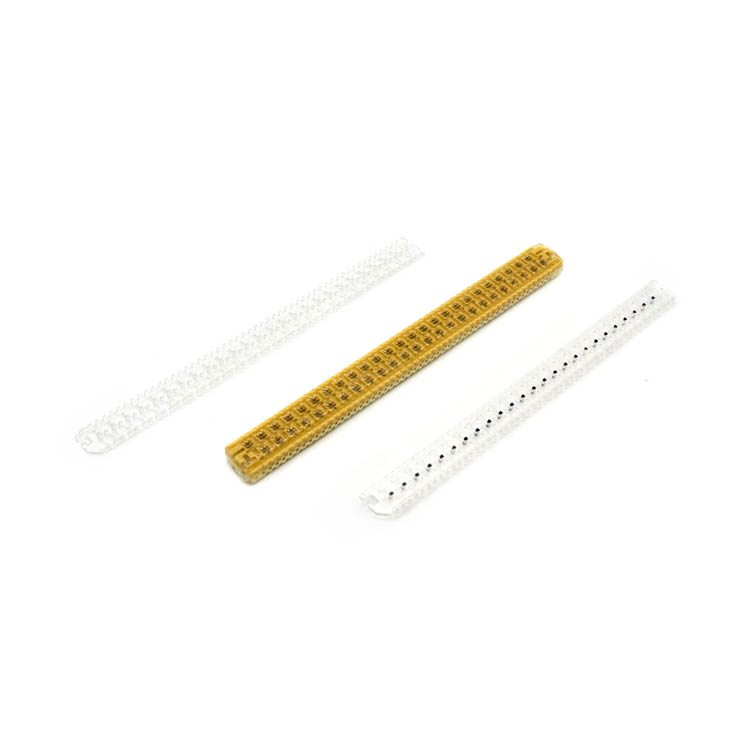

| Drop wire connector: | Gauge range 0.4 to 1.0mm |

| insulation diameter: | 5.0mm max |

| Pair connector: | Gauge range 0.4 to 1.0mm |

| insulation diameter: | 3.0mm max |

| Current conducting capacity | |

| 20A 10A per connector for 10 minutes at least without causing deformation of the module( if 20A up to 30A is required, this is possible using a different GDT) | |

| Insulation resistance | |

| Dry atmesphere | >10^12 Ω |

| Damp atmesphere(ASTMD618) | >10^12 Ω |

| Salt fog(ASTMB117) | >10^12 Ω |

| Immersion in water | >10^12 Ω |

| (15 days in 3% NaCi solution) | |

| Increase in contact resistance | |

| After climatic tests | 2.5m |

| After 50 reinsertions | 2.5m |

| Dielectric strength | 3000 Vdc for 1 minutes |

| Mechanical characteristics | |

| Pair/drop qire housing screw | Special passivated direct+lacquered zamac alloy |

| Drop wire housing body | Transparent polycarbonate |

| Body | Flame retardant (UL 94) glass-fiber reinforced polycarbonate |

| Insertion contacts | Tinned phosphor bronze |

| Ground contacts | Cu-Zn-Ni-Ag alloy |

| Lower sealant | Epoxy resin |

| Upper cable sealant | Silicone filled |

| Pair/drop wire bearing cover | Polycarbonate |

| Continuity contacts | Tinned hard brass |

| Pair/drop wire bearing cover | Polycarbonate |

| Plug-in module body | Flame retardant (UL 94) glass-fiber reinforced polycarbonate |

| Plug-in module sealant | Gel |

| "O"-Ring | EPDM |

| Spring | Stainless steel |

| Cable/drop wire membrance | Thermoplastic rubberC |

The terminal block of connection adapts for connecting the distributive wires of external and internal padding. Its construction provides the possibility of conducting the control measurements of the connected chains before both directions. Box provides protection from the environmental effects.

The terminal block of connection consists of housing and cover of rectangular form, and also 5- polar unit of connection, fixed on the housing. Cover is fixed beyond the axis common with the housing; however, it can be isolated from the housing for guaranteeing the convenience in the work due to the squeezed conditions. The introduction of wires is accomplished through the detachable stuffing boxes, which ensure the possibility of applying the wires of different sizes. Fastening wires is accomplished by the metallic screws, located inside the unit of connection.

| Products Specifications | |

| Contact characteristics | |

| Drop wire connector: | Gauge range 0.4 to 1.0mm |

| insulation diameter: | 5.0mm max |

| Pair connector: | Gauge range 0.4 to 1.0mm |

| insulation diameter: | 3.0mm max |

| Current conducting capacity | |

| 20A 10A per connector for 10 minutes at least without causing deformation of the module( if 20A up to 30A is required, this is possible using a different GDT) | |

| Insulation resistance | |

| Dry atmesphere | >10^12 Ω |

| Damp atmesphere(ASTMD618) | >10^12 Ω |

| Salt fog(ASTMB117) | >10^12 Ω |

| Immersion in water | >10^12 Ω |

| (15 days in 3% NaCi solution) | |

| Increase in contact resistance | |

| After climatic tests | 2.5m |

| After 50 reinsertions | 2.5m |

| Dielectric strength | 3000 Vdc for 1 minutes |

| Mechanical characteristics | |

| Pair/drop qire housing screw | Special passivated direct+lacquered zamac alloy |

| Drop wire housing body | Transparent polycarbonate |

| Body | Flame retardant (UL 94) glass-fiber reinforced polycarbonate |

| Insertion contacts | Tinned phosphor bronze |

| Ground contacts | Cu-Zn-Ni-Ag alloy |

| Lower sealant | Epoxy resin |

| Upper cable sealant | Silicone filled |

| Pair/drop wire bearing cover | Polycarbonate |

| Continuity contacts | Tinned hard brass |

| Pair/drop wire bearing cover | Polycarbonate |

| Plug-in module body | Flame retardant (UL 94) glass-fiber reinforced polycarbonate |

| Plug-in module sealant | Gel |

| "O"-Ring | EPDM |

| Spring | Stainless steel |

| Cable/drop wire membrance | Thermoplastic rubberC |