Double sheath All Dielectric Self-supporting Outdoor Aerial cable

Characteristics

- Can be installed without shutting off the power

- Excellent AT performance, The maximum inductive at the operating point of AT sheath can reach 25kV

- Light weight and small diameter reducing the load caused by ice and wind and the load on towers and backprops

- Large span lengths and the largest span is over 1000m

- Good performance of tensile strength and temperature

- The design life span is 30 years

Standards

ADSS Cable complies with IEEE1222,IEC60794-4-20,ANSI/ICEA S-87-640,TELCORDIA GR-20,IEC 60793-1-22,IEC 60794-1-2,IEC60794

Optical Fiber Specification

| Parameters | Specification | |||

| Optical Characteristics | ||||

| Fiber Type | G652.D | |||

| Mode Field Diameter (um) | 1310nm | 9.1± 0.5 | ||

| 1550nm | 10.3± 0.7 | |||

| Attenuation Coefficient (dB/km) | 1310nm | ≤0.35 | ||

| 1550nm | ≤0.21 | |||

| Attenuation Non-uniformity (dB) | ≤0.05 | |||

| Zero Dispersion Wavelength ( λo) (nm) | 1300-1324 | |||

| Max Zero Dispersion Slope (Somax) (ps/(nm2.km)) | ≤0.093 | |||

| Polarization Mode Dispersion Coefficient (PMDo) (ps/km1 / 2 ) | ≤0.2 | |||

| Cut-off Wavelength (λcc)(nm) | ≤1260 | |||

| Dispersion Coefficient (ps/ (nm·km)) | 1288~1339nm | ≤3.5 | ||

| 1550nm | ≤18 | |||

| Effective Group Index of Refraction (Neff) | 1310nm | 1.466 | ||

| 1550nm | 1.467 | |||

| Geometric characteristic | ||||

| Cladding Diameter (um) | 125.0± 1.0 | |||

| Cladding Non-circularity(%) | ≤1.0 | |||

| Coating Diameter (um) | 245.0± 10.0 | |||

| Coating-cladding Concentricity Error (um) | ≤12.0 | |||

| Coating Non-circularity (%) | ≤6.0 | |||

| Core-cladding Concentricity Error (um) | ≤0.8 | |||

| Mechanical characteristic | ||||

| Curling(m) | ≥4.0 | |||

| Proof stress(GPa) | ≥0.69 | |||

| Coating Strip Force (N) | Average Value | 1.0~5.0 | ||

| Peak Value | 1.3~8.9 | |||

| Macro Bending Loss (dB) | Φ60mm,100 Circles, @ 1550nm | ≤0.05 | ||

| Φ32mm,1 Circle, @ 1550nm | ≤0.05 | |||

Fiber Color Code

Fiber color in each tube starts from No. 1 Blue

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

Blue |

Orange |

Green |

Brown |

Gray |

White |

Red |

Black |

Yellow |

Purple |

Pink | Aqur |

Cable Technical Parameter

| Parameters |

Specification |

||||||||

| Fiber count |

2 |

6 |

12 |

24 |

60 |

144 | |||

| Loose Tube | Material | PBT | |||||||

| Fiber per Tube |

2 |

4 |

4 |

4 |

12 |

12 |

|||

| Numbers |

1 |

2 |

3 |

6 |

5 |

12 |

|||

| Filler Rod | Numbers |

5 |

4 |

3 |

0 |

1 |

0 |

||

| central strength Member | Material | FRP | FRP coated PE | ||||||

| Water blocking material | Water blocking yarn | ||||||||

| Addlitional strength Member | Aramid yarns | ||||||||

| Inner Jacket | Material | Black PE (Polythene) | |||||||

| Thickness | Nominal: 0.8 mm | ||||||||

| Outer Jacket | Material | Black PE (Polythene) or AT | |||||||

| Thickness | Nominal: 1.7 mm | ||||||||

| Cable Diameter(mm) |

11.4 |

11.4 |

11.4 |

11.4 |

12.3 | 17.8 | |||

| Cable Weight(kg/km) |

94~101 |

94~101 |

94~101 |

94~101 |

119~127 | 241~252 | |||

| Rated Tension Stress (RTS)(KN) |

5.25 |

5.25 |

5.25 |

5.25 |

7.25 | 14.25 | |||

| Maximum Working Tension (40%RTS)(KN) |

2.1 |

2.1 |

2.1 |

2.1 |

2.9 | 5.8 | |||

| Everyday Stress (15-25%RTS)(KN) |

0.78~1.31 |

0.78~1.31 |

0.78~1.31 |

0.78~1.31 |

1.08~1.81 | 2.17~3.62 | |||

| Allowable Maximum Span (m) | 100 | ||||||||

| Crush Resistance (N/100mm) | Short time | 2200 | |||||||

| Suiting Meteorological Condition | Max wind speed: 25m/s Max icing: 0mm | ||||||||

| Bending Radius (mm) | Installation | 20D | |||||||

| Operation | 10D | ||||||||

| Attenuation (After Cable)(dB/km) | SM Fiber @1310nm | ≤0.36 | |||||||

| SM Fiber @1550nm | ≤0.22 | ||||||||

| Temperature Range | Operation (°C) | - 40~+70 | |||||||

| Installation (°C) | - 10~+50 | ||||||||

| Storage & shipping (°c) | - 40~+60 | ||||||||

Application

1. Self-support Aerial installation

2. For overhead power lines under 110kv, PE outer sheath is applied.

3. For overhead power lines equal to or over 110ky, AT outer sheath is applied

Package

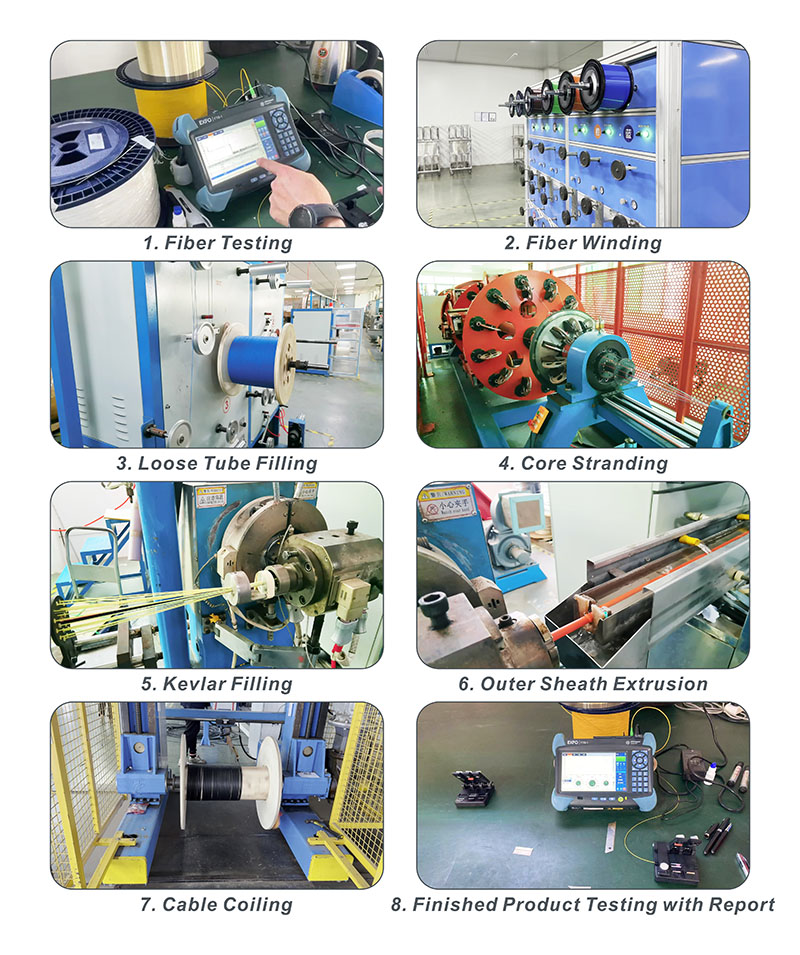

Production Flow

Cooperative Clients

FAQ:

1. Q : Are you trading company or manufacturer?

A : 70% of our products we manufactured and 30% do trading for customer service.

2. Q : How can you ensure the quality?

A : Good question! We are a one-stop manufacturer. We have complete facilities and over-15- years manufacturing experience to ensure product quality. And we have already passed ISO 9001 Quality Management System.

3. Q : Can you provide samples ? Is it free or extra?

A : Yes, After price confirmation , we could offer the free sample, but the shipping cost need pay for by your side.

4. Q : How long is your delivery time ?

A : In stock: In 7 days; No in stock: 15~20 days, depend on your QTY.

5. Q: Can you do OEM?

A: Yes , we can.

6. Q: What is your payment term ?

A: Payment <=4000USD,100% in advance. Payment>= 4000USD, 30% TT in advance, balance before shipment.

7. Q: How we can pay?

A: TT, Western Union , Paypal ,Credit Card and LC.

8. Q: Transportation?

A: Transported by DHL, UPS, EMS, Fedex, Air freight, Boat and Train.