High Density HDPE Micro Pipe Duct For Fiber Optical Cable

Product Video

Description

Micro Ducts of high density polyethylene with HDPE as the main raw material, are the composite pipe with inner wall made of silicon material lining made by the advanced plastic extrusion forming technology, the inner wall of this duct is a solid permanent lubrication layer, which has self-lubricity and effectively reduce the friction resistance between the cable and duct when the cable is repeatedly extracting in the duct.

● Optimizes system design and utilization

● Available in various sizes

● Single and multiple (bundled) configurations for specific project needs

● Permanently lubricated with our unique Perma-LubeTM process for longer micro fiber cable installations

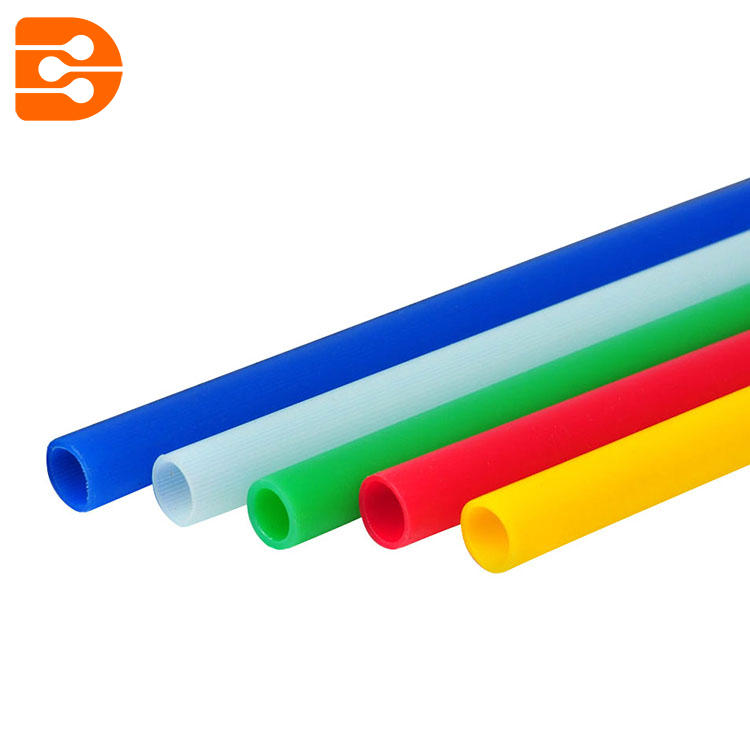

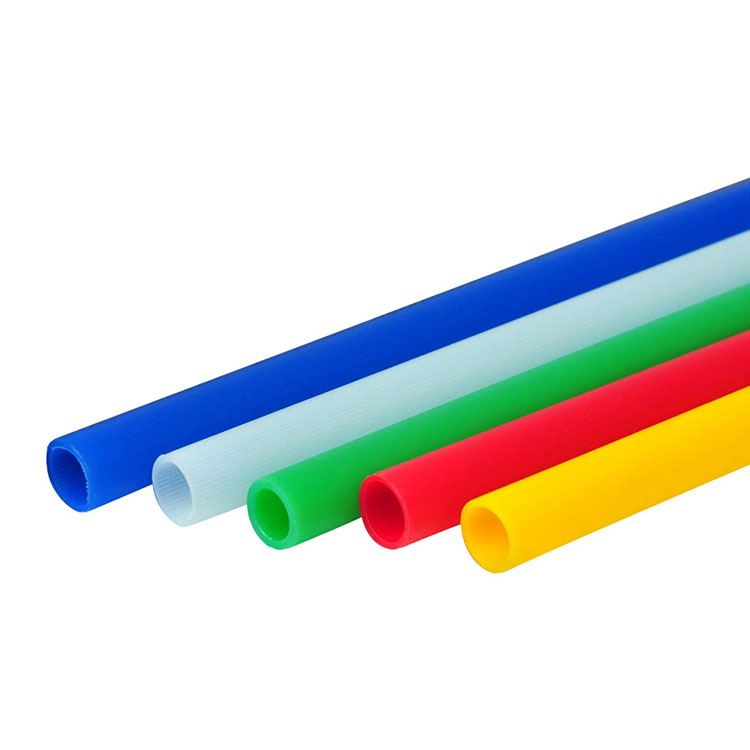

● Variety of colors available for easy identification

● Sequential foot or meter markings

● Standard stock lengths for faster service

● Custom lengths are also available

| Item No. | Raw Materials | Physical and Mechanical Properties | ||||||||||||||||

| Materials | Melt Flow Index | Density | Environmental Stress Crack Resist (F50) |

Outer Diameter | Wall Thickness | Inner Diameter Clearance | Ovality | Pressurization | Kink | Tensile Strength | Heat Reversion | Co-efficient of Friction | Color and Printing | Visual Appearance | Crush | Impact | Min. Bend Radius | |

| DW-MD0535 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 5.0mm ± 0.1mm | 0.75mm ± 0.10mm | A 3.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤ 50mm | ≥ 185N | ≤ 3% | ≤ 0.1 | As per customer specification | Ribbed inside & smooth outside surface, free from blisters, shrink hole, flaking, scratches & roughness. | No residual deformation > 15% of inner and outer diameter, shall pass inner diameter clearance test. | ||

| DW-MD0704 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 7.0mm ± 0.1mm | 1.50mm ± 0.10mm | A 3.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤ 70mm | ≥ 470N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD0735 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 7.0mm ± 0.1mm | 1.75mm ± 0.10mm | A 3.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤ 70mm | ≥520N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD0755 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 7.0mm ± 0.1mm | 0.75mm ± 0.10mm | A 4.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤ 70mm | ≥265N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD0805 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 8.0mm ± 0.1mm | 1.50mm ± 0.10mm | A 3.5mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤ 80mm | ≥550N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD0806 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 8.0mm ± 0.1mm | 1.00mm ± 0.10mm | A 4.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤ 80mm | ≥385N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD1006 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 10.0mm ± 0.1mm | 2.00mm ± 0.10mm | A 4.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤100mm | ≥910N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD1008 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 10.0mm ± 0.1mm | 1.00mm ± 0.10mm | A 6.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤100mm | ≥520N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD1208 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 12.0mm ± 0.1mm | 2.00mm ± 0.10mm | A 6.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤120mm | ≥1200N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD1210 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 12.0mm ± 0.1mm | 1.00mm ± 0.10mm | A 8.5mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤120mm | ≥620N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD1410 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 14.0mm ± 0.1mm | 2.00mm ± 0.10mm | A 8.5mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤140mm | ≥1350N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD1412 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 14.0mm ± 0.1mm | 1.00mm ± 0.10mm | A 9.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤140mm | ≥740N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD1612 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 16.0mm ± 0.15mm | 2.00 ± 0.10mm | A 9.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤176mm | ≥1600N | ≤ 3% | ≤ 0.1 | As per customer specification | ||||

| DW-MD2016 | 100% virgin HDPE | ≤ 0.40 g/10min | 0.940~0.958 g/cm3 | Min. 96h | 20.0mm ± 0.15mm | 2.00 ± 0.10mm | A 10.0mm steel ball can be blown freely through the duct. | ≤ 5% | No damage and leakage | ≤220mm | ≥2100N | ≤ 3% | ≤ 0.1 | As per customer specific | ||||

pictures

Application

Micro Ducts are suitable for the installation of fiber units and/or micro cables containing between 1 and 288 fibers. Dependent on the individual micro duct diameter, tube bundles are available in several types such as DB (direct bury), DI (direct install) and making them ideal for diverse applications such as long-distance bone network, WAN, in-building, campus and FTTH. They can also be customized to meet other specific applications.

product Testing

Certifications

Our Company