Optical fiber splice closures play a vital role in maintaining the reliability of telecom networks. They protect spliced connections from environmental damage, ensuring uninterrupted data transmission. Choosing the right closure prevents avoidable issues, reduces maintenance costs, and enhances network efficiency. Closures compatible with various fiber cable types, including multimode fiber cable and other optical fiber cable options, simplify installation and future expansions.

Key Takeaways

- Pick the right fiber optic splice closure to keep connections safe. This helps data flow smoothly and lowers repair costs.

- Think about where it will be used when choosing a closure. Dome closures work well outside, while inline closures are good underground.

- Check if it fits the cables and handles enough splices. A good match makes the network stronger and ready for growth.

Understanding Fiber Optic Splice Closures

What Is a Fiber Optic Splice Closure?

A fiber optic splice closure is a protective device that safeguards the spliced connections of optical fiber cables. It creates a sealed environment to shield these connections from external elements like water, dust, and extreme temperatures. This ensures the long-term performance of your network. These closures also organize and secure the fibers, making maintenance and troubleshooting easier. Whether you are working on an underground or aerial installation, a splice closure plays a critical role in maintaining the integrity of your fiber optic network.

Importance of Fiber Optic Closures in Telecom Projects

Fiber optic closures are essential for the reliability of telecom projects. They protect fiber connections from environmental hazards, such as moisture and dust, which can cause data loss. Their robust design withstands physical damage, ensuring uninterrupted signal quality. These closures also maintain performance across a wide range of temperatures, making them ideal for outdoor installations. By investing in a high-quality fiber splice box, you reduce maintenance costs and extend the lifespan of your network. This makes them a cost-effective solution for long-term projects.

Key Components of a Fiber Joint Closure

A fiber joint closure consists of several key components, each serving a specific purpose:

| Component | Function |

|---|---|

| Casing | Protects against environmental hazards, physical stress, and chemical exposure. |

| The Seal | Prevents water and air from entering, maintaining integrity at extreme temperatures. |

| Splice Trays | Organizes and protects fiber splices, facilitating easy maintenance. |

| Cable Entry Ports | Allows various cable sizes to pass through while maintaining enclosure integrity. |

| Strength Member Attachment | Enhances mechanical stability and safeguards fibers from tension and bending. |

| Grounding and Bonding Hardware | Provides electrical continuity and surge protection. |

| Fiber Slack Storage | Prevents damage from bending and maintains signal transmission levels. |

These components work together to ensure the durability and efficiency of your fiber optic closure. By understanding their roles, you can choose the right closure for your project and ensure optimal performance.

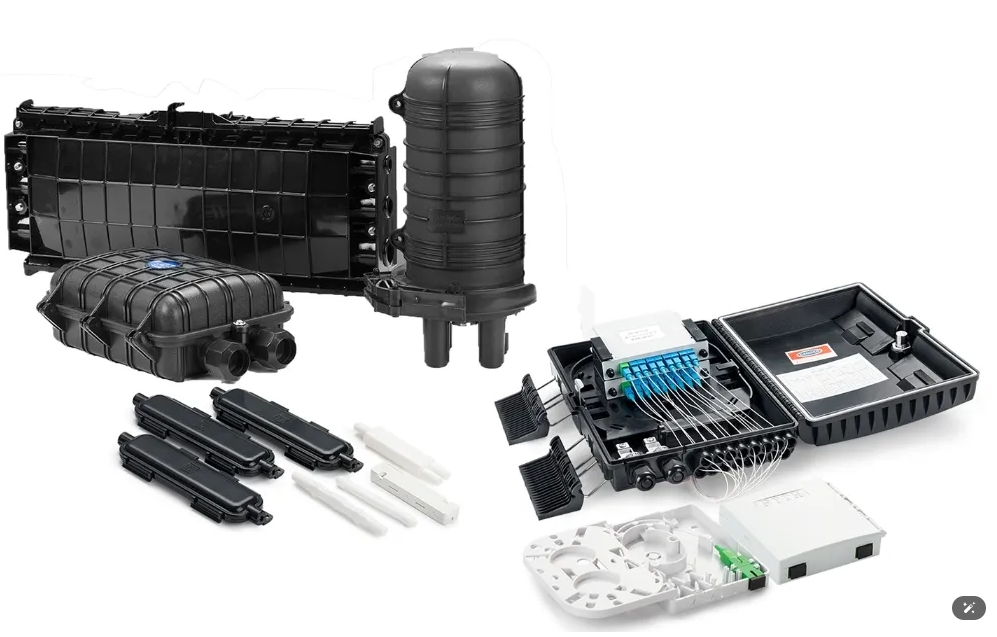

Types of Fiber Optic Splice Closures and Their Applications

Dome Fiber Optic Splice Closures: Features and Use Cases

Dome fiber optic splice closures, also known as vertical closures, are ideal for outdoor environments. Their cylindrical design ensures excellent protection against environmental factors. These closures feature a clamp and O-ring system, providing secure sealing and water resistance. They also include both mechanical and heat-shrinkable seals, making installation straightforward.

You can use dome closures in aerial, underground, and manhole installations. Their UV-resistant and waterproof construction ensures durability in harsh conditions. Dome closures are compatible with various optical fiber cable types, including single fiber and ribbon cables. Additionally, their reusable design simplifies maintenance without requiring special tools. This makes them a reliable choice for long-term projects.

Inline Horizontal Fiber Optic Closures: Features and Use Cases

Inline horizontal fiber optic closures, often referred to as inline splice closures, offer versatility for different installations. Their linear design aligns with the cable path, making them suitable for underground and aerial applications. These closures excel in backbone network setups due to their strong adaptability.

The horizontal design ensures easy installation and maintenance. High-quality materials enhance their sealing performance, protecting fiber connections from environmental damage. Inline closures also support mid-span access, allowing you to add or remove cables without cutting the main line. This feature makes them a practical option for expanding networks efficiently.

Inline Clamshell Splice Closures: Features and Use Cases

Inline clamshell splice closures stand out for their user-friendly design. Their flat, elongated structure fits well in tight spaces, making them ideal for underground installations. The clamshell opening simplifies cable management, allowing you to add or remove cables with ease.

These closures provide essential protection for splicing applications. They are commonly used to connect identical cables or extend fiber to the home networks. With a wide range of core capacities, clamshell closures adapt to various network scales, ensuring stable and uninterrupted signal transmission.

Comparing Types of Fiber Optic Closures for Different Projects

When choosing between types of fiber optic closure, consider several factors. First, assess the environment. Dome closures work best outdoors due to their water resistance and durability. Inline closures, on the other hand, suit underground installations or areas with limited space.

Next, evaluate capacity. Dome closures accommodate more splices, making them suitable for large-scale networks. Inline closures are better for smaller setups or mid-span access. Finally, prioritize ease of installation and maintenance. Clamshell designs simplify handling, while dome closures offer robust protection for long-term reliability.

How to Choose the Right Fiber Optic Splice Closure

Cable Compatibility: Matching with Optical Fiber Cable Types

Matching the fiber optic splice closure with your optical fiber cable is essential for optimal performance. You should evaluate the cable compatibility needs to avoid network issues. Consider the following factors:

- The number of cable ports determines how many cables the closure can support.

- A reliable termination system ensures efficient data transmission.

- The types of splices used impact the quality of connections.

By addressing these aspects, you can select a closure that meets your network's specifications and enhances its reliability.

Splicing Capacity: Ensuring Adequate Room for Fiber Splices

Splicing capacity directly impacts your network's scalability and performance. A closure with higher capacity supports growing networks and minimizes signal loss at splice points. It also accommodates multiple splicing points, ensuring efficient data transmission. Choosing the right splice closure reduces maintenance costs and prepares your network for future expansions.

Sealing Mechanisms: Protecting Against Environmental Factors

Effective sealing mechanisms protect fiber optic closures from environmental threats like water, dust, and extreme temperatures. Modern closures use advanced systems such as heat-shrink and gel-based seals. These innovations enhance resistance to moisture and debris. Mechanical seals with improved gaskets and clamps also provide durability and reusability, ensuring long-term protection for your fiber splice box.

Environmental Protection: IP Ratings and Durability Standards

IP ratings indicate the level of protection a fiber optic closure offers against solids and liquids. For outdoor installations, an IP68 rating ensures full dust protection and water resistance up to 1.5 meters. Durable materials like polycarbonate or ABS enhance the closure's lifespan. These features maintain network reliability even in harsh conditions, making them vital for fiber to the home and fiber to the x projects.

Installation Requirements: Ease of Use and Maintenance

Simplifying installation and maintenance reduces downtime and operational costs. Closures with modular components and easily removable covers make inspections and repairs straightforward. Regular maintenance, such as cleaning and testing, ensures the integrity of connections. Following manufacturer guidelines helps you avoid common challenges like improper cable preparation or exceeding the bend radius.

Why Dowell's Single Sheath Self-Supporting Optical Fiber Cable Is Ideal for Aerial Installations

Dowell's Single Sheath Self-Supporting Optical Fiber Cable offers unmatched performance for aerial installations. Its lightweight design minimizes wind and ice impact, reducing stress on support structures. The cable's all-dielectric construction eliminates the need for grounding, enhancing safety. With a lifespan of up to 30 years, it withstands harsh environmental conditions, ensuring reliable connections. This makes it an excellent choice for outdoor communication networks.

Additional Considerations for Telecom Projects

Bonding and Grounding for Electrical Safety

Proper bonding and grounding ensure the safety and reliability of your telecom network. These practices protect both equipment and personnel from electrical hazards. To achieve this, follow these best practices:

- Adhere to manufacturer guidelines and industry standards during installation.

- Ensure proper sealing, cable retention, and grounding for all splice closures.

- Conduct regular inspections to verify the integrity of bonding and grounding systems.

| Practice | Description |

|---|---|

| Bonding | Connects metal parts within devices to create a shared circuit for safe electricity discharge. |

| Grounding | Provides a safe path for fault current dissipation, protecting personnel and equipment. |

Neglecting bonding and grounding can lead to safety hazards, external noise interference, and difficulty locating underground cables. By prioritizing these measures, you enhance the durability and performance of your network.

Hardware and Accessories for Fiber Joint Closures

The right hardware and accessories improve the functionality and lifespan of your fiber joint closures. Essential components include:

- Bonding components for secure grounding.

- Cable management systems to control bending and prevent damage.

- Sealing materials like shrink tubing or self-amalgamating tapes to protect against environmental factors.

| Hardware/Accessory | Description |

|---|---|

| Attachment Hardware | Used for hanging closures on messenger wires or poles, withstands stress. |

| Cable Management Systems | Ensures secure grounding and controls cable bending. |

| Sealing Materials | Prevents water, dust, and corrosion for long-lasting protection. |

When selecting these components, consider environmental resistance, ease of installation, and compatibility with your optical fiber cable. These factors ensure your network remains robust and efficient.

Balancing Cost and Performance for Long-Term Value

Balancing cost and performance involves choosing closures that meet your network's needs while ensuring long-term savings. High-quality closures may require a higher initial investment, but they reduce maintenance costs and minimize downtime. This enhances operational efficiency and lowers the total cost of ownership.

To achieve this balance:

- Evaluate environmental conditions, installation type, and network architecture.

- Invest in closures that offer durability and scalability for future expansions.

- Prioritize reliability to ensure consistent performance over time.

By focusing on these aspects, you create a network that delivers dependable service while optimizing costs.

Choosing the right fiber optic splice closure ensures network reliability and performance. These closures protect connections from environmental hazards, reduce signal loss, and simplify maintenance. Key factors include environmental conditions, capacity, and durability. Evaluate your project needs carefully. Dowell’s innovative solutions offer the reliability and quality essential for long-term success.

FAQ

What is the lifespan of a fiber optic splice closure?

Most fiber optic splice closures last 20-30 years. Their durability depends on environmental conditions and the quality of materials used in their construction.

How do you maintain a fiber optic splice closure?

Inspect closures regularly for damage or wear. Clean the seals and check for water ingress. Follow the manufacturer’s guidelines to ensure optimal performance and longevity.

Can you reuse a fiber optic splice closure?

Yes, you can reuse many closures. Choose models with modular designs and durable seals. This simplifies maintenance and reduces costs for future network upgrades.

Post time: Feb-21-2025