Fiber optic splice closures play a vital role in safeguarding the integrity of modern communication networks. These closures protect fiber connections from environmental hazards like moisture, dust, and extreme temperatures. By ensuring secure splicing and organization of cables, they maintain signal quality and prevent data loss. Their robust design withstands physical damage, reducing the risk of network interruptions. With the growing demand for high-speed internet and reliable connectivity, fiber optic splice closures have become indispensable for enhancing network performance and minimizing downtime.

Key Takeaways

- Fiber optic splice closures protect delicate fiber connections from environmental hazards like moisture, dust, and extreme temperatures, ensuring uninterrupted network performance.

- These closures enhance signal integrity by minimizing signal loss at splice points, which is crucial for maintaining high-speed data transmission.

- Investing in high-quality splice closures can significantly reduce long-term maintenance costs by extending the lifespan of fiber optic networks and minimizing the need for repairs.

- Proper installation and regular inspections of splice closures are essential for maintaining their protective capabilities and ensuring optimal network reliability.

- Choosing the right splice closure based on network requirements and environmental conditions is vital for achieving seamless integration and performance.

- The robust design of fiber optic splice closures allows for easy access and management of spliced fibers, simplifying maintenance tasks and reducing downtime.

What Is a Fiber Optic Splice Closure and Its Role in Network Infrastructure?

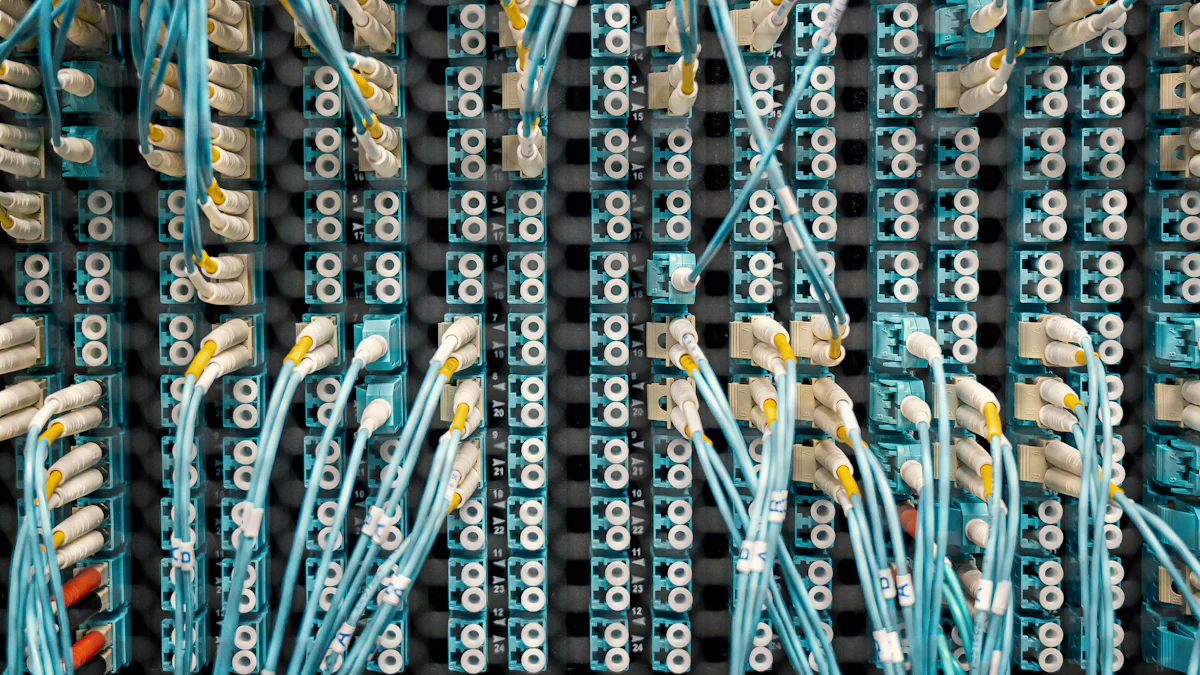

Fiber optic networks rely on precision and durability to deliver uninterrupted connectivity. A fiber optic splice closure serves as a critical component in ensuring this reliability. It protects spliced fiber optic cables, maintaining their integrity and shielding them from environmental and physical threats. By providing a secure and organized environment for fiber splicing, these closures play a pivotal role in the performance and longevity of network infrastructure.

Definition and Purpose of Fiber Optic Splice Closures

A fiber optic splice closure is a protective enclosure designed to house and safeguard spliced fiber optic cables. Its primary purpose is to create a sealed environment that prevents external factors like moisture, dust, and temperature fluctuations from damaging the delicate fiber connections. These closures also ensure proper cable management, reducing the risk of signal loss and maintaining high-quality data transmission.

In addition to protection, splice closures simplify network maintenance. They allow technicians to access and manage spliced fibers efficiently, minimizing downtime during repairs or upgrades. Whether used in telecommunications, data centers, or industrial networks, these closures are indispensable for maintaining network reliability.

How Fiber Optic Splice Closures Integrate Into Network Systems

Fiber optic splice closures integrate seamlessly into various network systems. They connect feeder cables to distribution cables, forming a vital link in FTTx backbone networks. Their design accommodates multiple splicing points, enabling scalability for expanding networks. For example, the 12 Port IP68 288F Horizontal Splicing Box supports up to 288 fibers, making it ideal for both urban and rural deployments.

These closures are versatile in installation. They can be mounted underground, on poles, or on walls, depending on the network’s requirements. Their robust construction ensures durability in diverse environments, from bustling cities to remote rural areas. By integrating fiber splicing, storage, and cable management into a single unit, splice closures streamline network operations and enhance overall efficiency.

Types of Fiber Optic Splice Closures

Fiber optic splice closures come in various types, each designed to meet specific application needs. The two most common types are dome-style closures and inline closures.

Dome-Style Closures

Dome-style closures feature a cylindrical design that provides excellent protection against environmental factors. Their dome-shaped structure ensures a tight seal, making them highly resistant to water and dust. These closures are often used in outdoor installations where exposure to harsh conditions is a concern. Their vertical orientation makes them suitable for pole-mounted applications.

Inline Closures

Inline closures, as the name suggests, have a linear design that aligns with the cable’s path. These closures are ideal for underground installations or areas with limited space. They offer easy access to spliced fibers and support mid-span access without cutting the cable. This feature simplifies maintenance and reduces the risk of network interruptions.

Both types of closures are constructed with high-tension plastic and other durable materials, ensuring long-term performance. Their designs cater to different network configurations, providing flexibility and reliability for various applications.

Key Benefits of Fiber Optic Splice Closures

Fiber optic splice closures offer a range of advantages that significantly enhance the reliability and efficiency of network systems. These benefits ensure that fiber optic networks remain robust, even in challenging environments.

Protection Against Environmental Factors

Resistance to moisture, dust, and temperature fluctuations

Fiber optic splice closures provide exceptional protection against environmental threats. Their sealed design prevents moisture and dust from infiltrating the enclosure, which could otherwise compromise the delicate fiber connections. This feature is particularly important in outdoor installations, where exposure to rain, humidity, and airborne particles is unavoidable. Additionally, these closures maintain their integrity across a wide range of temperatures, ensuring consistent performance in both extreme heat and freezing conditions.

Scientific Research Findings: Studies highlight that fiber optic splice closures are crucial for safeguarding cables against contaminants and environmental factors, ensuring long-term efficiency and reliability.

Durability in harsh outdoor conditions

The durability of fiber optic splice closures makes them indispensable for outdoor applications. Constructed with high-quality materials, such as impact-resistant plastics and anti-corrosive metals, these closures withstand physical stress and harsh weather. Whether installed underground, on poles, or in exposed areas, they protect fiber optic cables from mechanical damage caused by debris, animals, or accidental impacts. This resilience ensures uninterrupted network performance, even in the most demanding environments.

Improved Signal Integrity

Prevention of signal loss at splice points

Signal loss at splice points can disrupt data transmission and degrade network performance. Fiber optic splice closures address this issue by creating a controlled environment for splicing operations. Their design minimizes external interference, ensuring that the spliced fibers remain aligned and secure. This precision reduces the risk of signal attenuation, maintaining the high-speed connectivity that modern networks demand.

Enhanced data transmission quality

By safeguarding the splicing process, fiber optic splice closures contribute to superior data transmission quality. They prevent external factors, such as vibrations or temperature changes, from affecting the fiber connections. This stability ensures that data travels through the network without interruptions or degradation, supporting applications that require reliable and high-bandwidth communication.

Scientific Research Findings: Research confirms that fiber optic splice closures play a critical role in protecting splices, ensuring efficient and reliable data transmission across networks.

Reduced Downtime and Maintenance Costs

Minimizing network interruptions

Network interruptions can lead to significant downtime and lost productivity. Fiber optic splice closures help minimize these disruptions by providing a secure and organized environment for fiber splicing. Their robust construction reduces the likelihood of damage, while their design simplifies maintenance tasks. Technicians can access and manage the spliced fibers quickly, ensuring that repairs or upgrades are completed with minimal impact on network operations.

Lowering repair and replacement expenses

Investing in high-quality fiber optic splice closures reduces long-term maintenance costs. Their durability and protective features extend the lifespan of fiber optic networks, decreasing the need for frequent repairs or replacements. By preventing damage and ensuring reliable performance, these closures save organizations time and money, making them a cost-effective solution for network infrastructure.

Scientific Research Findings: The growing adoption of fiber optic splice closures reflects their ability to enhance network reliability while reducing operational costs.

Addressing Network Reliability Challenges With Fiber Optic Splice Closures

Fiber optic networks face numerous challenges that can compromise their reliability. I have seen how fiber optic splice closures effectively address these issues, ensuring stable and efficient network performance. Let me walk you through how these closures tackle environmental hazards, physical damage, and aging infrastructure.

Environmental Hazards

How splice closures prevent damage from weather and debris

Environmental factors like rain, dust, and debris pose significant risks to fiber optic networks. I have observed that a fiber optic splice closure acts as a shield, protecting delicate fiber connections from these external threats. Its sealed design prevents moisture and dust from entering, which could otherwise degrade the fiber’s performance. For outdoor installations, this protection becomes even more critical.

The robust construction of these closures ensures they withstand harsh weather conditions. Whether exposed to heavy rainfall or strong winds, they maintain their integrity. This durability minimizes the risk of network interruptions caused by environmental hazards. By using these closures, I have seen networks remain operational even in challenging environments.

Physical Damage to Fiber Optic Cables

Role of closures in protecting against accidental cuts or impacts

Accidental damage to fiber optic cables can disrupt network operations. I have noticed that fiber optic splice closures provide a secure enclosure that protects cables from physical harm. Their tough exterior resists impacts, whether caused by falling debris, construction activities, or wildlife interference.

These closures also simplify cable management, reducing the likelihood of accidental cuts during maintenance. I have found that their design ensures cables remain organized and secure, preventing unnecessary strain on the fibers. This protection extends the lifespan of the cables and reduces the frequency of repairs.

Aging Infrastructure

How closures extend the lifespan of fiber optic networks

Aging infrastructure presents another challenge for network reliability. Over time, wear and tear can weaken fiber optic connections. I have seen how fiber optic splice closures help mitigate this issue by providing a stable and protective environment for spliced fibers. Their durable materials resist corrosion and degradation, ensuring long-term performance.

By maintaining the integrity of fiber connections, these closures extend the lifespan of the network. I have observed that they reduce the need for frequent replacements, saving both time and resources. This makes them an essential component for modernizing and preserving aging network systems.

Expert Insight: Industry professionals agree that fiber optic splice closures play a vital role in addressing the challenges of environmental hazards, physical damage, and aging infrastructure. Their use enhances network reliability and ensures consistent performance.

Real-World Applications of Fiber Optic Splice Closures

Fiber optic splice closures have proven their value in diverse real-world scenarios. Their ability to protect, organize, and enhance fiber optic networks makes them indispensable in both urban and rural settings. Let me share some examples that highlight their practical applications.

Case Study: Urban Network Deployment

Urban areas demand robust and efficient network infrastructure to support high-speed internet services. I have seen how the 12 Port IP68 288F Horizontal Splicing Box excels in city networks. Its compact design and high capacity make it ideal for densely populated environments where space is limited but connectivity demands are high.

This splice closure integrates seamlessly into urban FTTH (Fiber to the Home) networks. It connects feeder cables to distribution cables, ensuring reliable data transmission across multiple splicing points. Its IP68-rated waterproof design protects against moisture and dust, which are common challenges in city installations. The rugged construction withstands vibrations and impacts caused by heavy traffic or construction activities. These features ensure uninterrupted connectivity for businesses, homes, and public services.

Key Insight: Urban deployments require solutions that combine durability, efficiency, and scalability. The 12 Port IP68 288F Horizontal Splicing Box meets these needs, making it a preferred choice for city networks.

Case Study: Rural Broadband Expansion

Rural areas often face unique challenges in achieving reliable connectivity. I have observed how the 12 Port IP68 288F Horizontal Splicing Box supports broadband expansion in these regions. Its versatility allows for underground, pole-mounted, or wall-mounted installations, adapting to the varied terrains of rural landscapes.

In rural deployments, this splice closure ensures stable connections over long distances. Its mechanical sealing structure prevents environmental factors like rain, dust, and temperature fluctuations from affecting the fiber optic cables. The mid-span access feature simplifies maintenance, reducing the need for extensive repairs. By enabling efficient and cost-effective network expansion, this splice closure plays a vital role in bridging the digital divide between urban and rural communities.

Real-World Impact: Reliable broadband connectivity transforms rural areas by improving access to education, healthcare, and economic opportunities. The 12 Port IP68 288F Horizontal Splicing Box contributes significantly to this transformation.

Lessons Learned From Real-World Applications

From my experience, several lessons emerge from the use of fiber optic splice closures in real-world scenarios:

- Environmental Resistance Matters: Whether in urban or rural settings, the ability to withstand harsh conditions ensures long-term network reliability.

- Ease of Installation and Maintenance: Features like mid-span access and organized cable management simplify network operations, saving time and resources.

- Scalability Is Key: High-capacity splice closures like the 12 Port IP68 288F Horizontal Splicing Box support growing networks, making them future-proof investments.

These lessons underscore the importance of selecting the right splice closure for specific network requirements. By doing so, organizations can achieve efficient, reliable, and sustainable connectivity.

Best Practices for Selecting and Maintaining Fiber Optic Splice Closures

Factors to Consider When Choosing a Splice Closure

Selecting the right fiber optic splice closure requires careful evaluation of several factors. I have found that understanding your network’s specific needs ensures optimal performance and long-term reliability.

Compatibility with Network Requirements

The first step in choosing a splice closure involves assessing its compatibility with your network’s requirements. I always recommend evaluating the closure’s capacity to handle the number of splicing points your network demands. For instance, closures like the 12 Port IP68 288F Horizontal Splicing Box accommodate up to 288 fibers, making them ideal for large-scale deployments. Additionally, consider the type of cables used in your network. Ensure the closure supports the cable diameter and splicing configurations you need.

Key Insight: Matching the splice closure’s specifications with your network’s design prevents future compatibility issues and ensures seamless integration.

Environmental and Durability Considerations

Environmental conditions play a significant role in the performance of splice closures. I always prioritize closures with robust designs that can withstand harsh environments. Features like IP68-rated waterproofing and resistance to dust ensure reliable operation in outdoor installations. Materials such as impact-resistant plastics and anti-corrosive metals enhance durability, protecting the fibers from physical damage and environmental hazards.

Expert Testimony:

“Maintenance convenience is a significant factor when considering fiber optic splice closures. These closures are often designed with accessibility in mind, featuring easily removable covers and modular components. This makes it easier to inspect and service the cables inside, reducing downtime and maintenance costs.”

By selecting closures built for durability, I have seen networks maintain consistent performance even in challenging conditions.

Tips for Proper Installation and Maintenance

Proper installation and regular maintenance are essential for ensuring the longevity and efficiency of fiber optic splice closures. I have learned that following best practices minimizes disruptions and extends the lifespan of your network infrastructure.

Regular Inspections for Wear and Tear

Routine inspections are crucial for identifying potential issues before they escalate. I recommend checking the closure’s seals, bolts, and cable entries for signs of wear or damage. Look for moisture or dust infiltration, as these can compromise the fiber connections. Regular inspections help maintain the closure’s integrity and prevent costly repairs.

Pro Tip: Schedule inspections at least twice a year, especially for closures installed in harsh outdoor environments.

Ensuring Proper Sealing and Cable Management

Proper sealing is vital for protecting the fibers from environmental factors. I always ensure that the closure’s seals are intact and securely fastened. Use high-quality rubber seals and clamps to prevent moisture and dust from entering the enclosure. Additionally, organized cable management within the closure reduces strain on the fibers and prevents accidental damage during maintenance.

Closures like the 12 Port IP68 288F Horizontal Splicing Box simplify cable management with features such as integrated splice cassettes and mid-span access. These features make it easier to organize and maintain the fibers, ensuring long-term reliability.

Key Takeaway: Proper sealing and cable management not only protect the fibers but also streamline maintenance tasks, saving time and resources.

By following these best practices, I have seen networks achieve enhanced reliability and reduced downtime. Investing time in selecting the right closure and maintaining it properly ensures your network remains robust and efficient.

Fiber optic splice closures, like the 12 Port IP68 288F Horizontal Splicing Box, play a pivotal role in ensuring network reliability. They shield fiber connections from environmental threats, reducing signal loss and enhancing dependability. Their robust design improves performance while minimizing downtime, making them indispensable for modern networks. I always recommend adopting best practices for selection and maintenance to achieve long-term stability. Investing in high-quality splice closures not only protects your network but also future-proofs its infrastructure, ensuring efficiency and reliability for years to come.

FAQ

What is the function of Fiber Optic Splice Closure?

Fiber optic splice closures serve as protective enclosures for spliced fiber optic cables. They shield these delicate connections from environmental factors like moisture, dust, and temperature fluctuations. Additionally, they ensure proper cable management, which minimizes signal loss and enhances data transmission quality. By selecting and installing closures that align with network requirements, such as cable compatibility and environmental durability, I have seen networks achieve greater efficiency and reliability.

Key Takeaway: Properly chosen and installed splice closures safeguard fiber optic systems, ensuring long-term performance and protection.

What is the importance of Fiber Optic Splice Closure?

Fiber optic splice closures are essential for maintaining the integrity of fiber optic networks. They provide a secure environment for spliced fibers, ensuring low-loss and high-performance connections. Their robust design withstands harsh conditions, making them indispensable for outdoor and indoor installations. As demand for high-speed networks grows, I believe these closures will continue to evolve, offering advanced solutions to meet future connectivity needs.

Expert Insight: Proper installation and regular maintenance of splice closures ensure their optimal performance and longevity.

How to manage Fiber Optic Splice Closure effectively?

Effective management of fiber optic splice closures begins with proper fiber routing. I always recommend organizing fibers systematically within the closure to prevent strain and damage. Regular inspections for wear and tear, along with ensuring secure seals, help maintain their protective capabilities. Closures like the 12 Port IP68 288F Horizontal Splicing Box simplify management with features like integrated splice cassettes and mid-span access.

Pro Tip: Streamline fiber routing to make maintenance faster and reduce the risk of network interruptions.

What are the characteristics of Fiber Optic Splice Closure?

Fiber optic splice closures are compact, rugged enclosures made from high-tension plastic or similar durable materials. They feature moisture barriers and aging-resistant components, ensuring protection against ultraviolet light and other environmental elements. I have observed that their robust construction makes them ideal for safeguarding sensitive fiber optic connections in both urban and rural deployments.

Key Feature: Their durability ensures reliable performance even in extreme conditions.

What role does Fiber Optic Splice Closure play in the market?

Fiber optic splice closures are pivotal in the expanding telecommunications industry. They support the growing demand for high-speed internet and reliable connectivity. I have noticed their increasing use in smart cities, IoT applications, and rural broadband projects. Market players focus on innovation and regional expansion to meet the rising need for these closures.

Market Insight: The future of fiber optic splice closures looks promising, with advancements catering to evolving network demands.

What are the benefits of using Fiber Optic Splice Closure?

Fiber optic splice closures offer numerous benefits, including protection against environmental hazards, improved signal integrity, and reduced maintenance costs. They enhance network reliability by preventing signal loss at splice points and ensuring stable data transmission. I have seen how their robust design minimizes downtime, making them a cost-effective solution for modern networks.

Lesson Learned: Investing in high-quality splice closures ensures long-term network stability and efficiency.

What advancements are expected in Fiber Optic Splice Closure?

The future of fiber optic splice closures lies in innovation. I anticipate advancements in materials and designs that further enhance durability and ease of use. Features like automated sealing mechanisms and improved fiber management systems will likely become standard. These innovations will address the growing need for high-bandwidth and low-latency networks.

Future Outlook: Continuous advancements will make splice closures even more reliable and efficient.

How does Fiber Optic Splice Closure provide protection?

Fiber optic splice closures protect spliced cables by creating a sealed environment that prevents moisture, dust, and mechanical damage. Their strong outer shells and secure sealing mechanisms ensure that fiber joints remain intact, even in hostile environments. I have found closures like the 12 Port IP68 288F Horizontal Splicing Box particularly effective in safeguarding connections in challenging conditions.

Key Insight: Reliable protection ensures uninterrupted network performance, even in harsh environments.

Why should I invest in high-quality Fiber Optic Splice Closures?

High-quality splice closures offer superior protection, durability, and ease of maintenance. They reduce the risk of network interruptions and extend the lifespan of fiber optic systems. I always recommend investing in closures that meet your network’s specific needs, as this ensures long-term reliability and cost savings.

Professional Advice: Quality splice closures are a worthwhile investment for future-proofing your network infrastructure.

Post time: Dec-04-2024