Fiber optic cable solutions have become the backbone of industrial telecom infrastructure, especially as global connectivity demands surge in 2025. The market for fiber optic cable is projected to grow from USD 13.45 billion to USD 36.48 billion by 2034, driven by its ability to support speeds exceeding 100 Gbps. These advancements cater to the bandwidth needs of 5G networks and cloud computing. Innovation plays a pivotal role, with technologies such as AI-driven network management and 10G-PON enabling faster, more efficient communication. Sustainable practices, like energy-efficient fiber optic cable for data center operations, further underline the industry’s commitment to reducing its carbon footprint. Additionally, the use of multimode fiber cable is becoming increasingly popular for various applications, including fiber optic cable for telecom, ensuring robust and reliable connectivity.

Key Takeaways

- Fiber optic cables are important for fast and steady internet. They can handle speeds over 100 Gbps.

- Single-mode fibers work well for long distances. They keep signals strong and are ready for future tech.

- Multi-mode fibers are cheaper for short distances. They are great for data centers and school networks.

- Armored cables are tougher and protect in rough conditions. They resist damage from weather and physical harm.

- Dowell makes smart fiber optic products. These improve connections and help modern industries.

Single-Mode Fiber Optic Cable

Features and Benefits

Single-mode fiber optic cables offer several advantages that make them indispensable for industrial telecom infrastructure. These cables provide greater bandwidth, enabling efficient data transmission for high-demand applications. Their ability to transmit signals over extended distances, often exceeding 80 kilometers without the need for signal boosters, makes them ideal for long-range communication networks. Additionally, single-mode fibers exhibit reduced signal loss due to minimal modal dispersion, ensuring strong and reliable signal quality. With attenuation rates as low as 0.4 dB/km at 1310 nm, they deliver exceptional performance in maintaining signal integrity.

Another key benefit is their future-proofing capability. Single-mode fibers support advanced technologies like Dense Wavelength Division Multiplexing (DWDM), allowing for easy scalability as network demands grow. Their compact design facilitates high-density installations, while their robust construction ensures reliability even in harsh environments. These features make them suitable for applications ranging from telecommunications to military and aerospace operations.

Applications in Long-Distance Telecom

Single-mode fiber optic cables play a critical role in long-distance telecommunications. The increasing demand for higher bandwidth and faster internet connections has driven their adoption in industrial telecom infrastructure. These cables are essential for supporting activities such as video streaming, online gaming, and social media, which require substantial data transmission capabilities. Their ability to maintain signal quality over vast distances ensures seamless connectivity for users.

The rise of 5G technology has further amplified the importance of single-mode fibers. As 5G networks require high-speed, low-latency connections, these cables provide the backbone for next-generation wireless communication. They enable faster download and upload speeds, lower latency, and increased network capacity, making them indispensable for modern telecom systems. The ongoing development of advanced telecommunication systems continues to drive the demand for single-mode fibers, ensuring their relevance in future infrastructure advancements.

Multi-Mode Fiber Optic Cable

Features and Benefits

Multi-mode fiber optic cables are a cost-effective solution for industrial telecom applications. They are more affordable than single-mode fibers, making them an ideal choice for short-distance networks. Their simplified installation process, enabled by a larger core diameter, reduces alignment challenges and minimizes the need for specialized skills. This ease of installation also translates to lower maintenance costs over time.

These cables excel in environments with electromagnetic interference (EMI), ensuring reliable performance in industrial settings. They also maintain functionality under extreme temperatures, making them suitable for demanding applications. Multi-mode fibers support longer link distances compared to copper cables, offering superior performance for distances up to 550 meters. This capability makes them a preferred choice for campus networks, data centers, and other high-density environments.

The versatility of multi-mode fiber extends to specialized applications, including robotics and renewable energy systems. Their ability to handle high data rates, up to 100 Gbps over suitable distances, ensures they meet the demands of modern industrial networks. The growing market for multi-mode fiber optic cables reflects their effectiveness, with projections indicating a compound annual growth rate (CAGR) of 11.2% from 2025 to 2033.

| Feature/Benefit | Description |

|---|---|

| Lower cost | More affordable than single-mode fiber, making it cost-effective for industrial use. |

| Ease of installation | Simplified installation and maintenance processes. |

| Suitability for shorter distances | Ideal for applications within buildings and campuses, typically under 550 meters. |

| Immunity to EMI interferences | Provides reliable performance in environments with electromagnetic interference. |

| Superior performance under high temperatures | Maintains functionality in extreme temperature conditions. |

| Longer link distances than copper | Offers greater distances compared to copper or plastic optical fiber (POF). |

| Applications in robotics and renewable energy | Specifically designed for use in robotics, wind power, and solar energy systems. |

Applications in Short-Distance Networks

Multi-mode fiber optic cables are widely used in short-distance networks due to their affordability and efficiency. Their larger core diameter allows for the use of less expensive light sources, making them a cost-effective solution for installations requiring short to medium distances. This feature is particularly beneficial for high-density environments such as data centers and campus networks.

The simplified installation process of multi-mode fibers reduces the time and expertise required for deployment. This advantage makes them an attractive option for organizations seeking to expand their digital infrastructure quickly. Multi-mode fibers also support high-speed data transmission, with capabilities of up to 100 Gbps over appropriate distances. This performance ensures they meet the demands of modern applications, including video streaming, cloud computing, and IoT devices.

The deployment of multi-mode fibers plays a crucial role in the development of 5G infrastructure. Their ability to handle high bandwidth and low latency requirements makes them indispensable for supporting next-generation telecom networks. As digital infrastructure continues to expand, the demand for multi-mode fiber optic cables is expected to grow significantly.

- Cost-effective solution for short-distance applications, using less expensive light sources.

- Simplified installation and maintenance due to the larger core diameter.

- Superior bandwidth capabilities, supporting data rates of up to 100 Gbps in high-density environments.

Armored Fiber Optic Cable

Features and Benefits

Armored fiber optic cables are engineered to endure the most demanding industrial conditions. These cables feature multiple protective layers, including a durable plastic outer jacket and a light steel tube, which enhance their safety and resilience. The steel tube is further reinforced with Kevlar, offering superior protection against abrasion, twisting, and other physical stresses. This robust construction ensures the cables remain functional even in environments prone to mechanical damage.

There are two primary types of armored fiber optic cables: aluminum interlock armored (AIA) and stainless steel micro-armor. AIA cables provide excellent protection against crushing and impact, while stainless steel micro-armor offers enhanced flexibility and lightweight properties. Both types are designed to meet the specific needs of industrial applications, ensuring reliable performance in diverse settings.

Unlike standard fiber optic cables, which are vulnerable to crushing, weathering, and rodent damage, armored fiber optic cables are significantly tougher and more durable.

These cables are also designed to withstand harsh environmental factors, such as moisture and rodent attacks. Military-grade armored cables are particularly suited for mission-critical networks, offering unmatched durability and reliability. Additionally, innovations like the SteelFlex Armored Fiber Optic Cable with an OptoLock mechanism reduce installation costs by eliminating the need for conduit systems. Their lightweight and flexible design further simplifies installation, making them a cost-effective solution for various industrial applications.

Applications in Harsh Industrial Environments

Armored fiber optic cables excel in environments where standard cables fail. Their rugged design makes them ideal for use in factories, mining operations, and other industrial settings where mechanical stress and environmental hazards are prevalent. These cables can withstand rodent attacks, moisture exposure, and extreme temperatures, ensuring uninterrupted connectivity in challenging conditions.

In outdoor installations, armored cables provide reliable performance even when buried underground or exposed to harsh weather. Their resistance to crushing and abrasion makes them suitable for heavy-duty applications, such as oil and gas pipelines, power plants, and transportation infrastructure. Military and defense sectors also rely on armored fiber optic cables for secure and durable communication networks in mission-critical operations.

The versatility of armored fiber optic cables extends to temporary installations in disaster recovery scenarios. Their robust construction ensures they can be deployed quickly and withstand the rigors of emergency environments. By offering unmatched durability and reliability, these cables play a vital role in maintaining connectivity in the most demanding industrial applications.

Ribbon Fiber Optic Cable

Features and Benefits

Ribbon fiber optic cables are designed to meet the demands of modern telecom infrastructure, offering a combination of high performance and efficiency. These cables feature a compact design with multiple fibers arranged in a flat, ribbon-like structure. This configuration allows for higher fiber density, making them ideal for environments where space is limited. Their ability to support high-speed data transmission ensures seamless connectivity, which is essential for applications like 5G networks and cloud computing.

The growing reliance on smartphones and IoT devices has significantly increased data consumption, further emphasizing the importance of ribbon fiber optic cables. Their design enables faster splicing and installation, reducing labor costs and minimizing downtime during deployment. Additionally, these cables are highly reliable, ensuring consistent performance even in demanding conditions.

Key advantages of ribbon fiber optic cables include:

- High fiber density and compact design, suitable for space-constrained environments.

- Efficient data transmission and high-speed connectivity for modern telecom applications.

- Cost and time savings due to faster installation processes.

- Increased demand driven by the exponential growth of data consumption from IoT devices and smartphones.

Applications in High-Density Data Centers

Ribbon fiber optic cables play a critical role in high-density data centers, where maximizing space and performance is a priority. Their compact design allows for higher fiber counts within a smaller footprint, making them an excellent choice for facilities with limited space. These cables also support advanced network speeds, ensuring they meet the demands of modern data center operations.

The following table highlights the features and benefits of ribbon fiber optic cables in high-density data centers:

| Feature/Benefit | Description |

|---|---|

| Time and Cost Savings | Ribbon cables allow for faster installation due to pre-banded fibers, reducing labor costs. |

| Increased Fiber Density | They provide higher fiber counts in a compact design, which is essential for high-density data centers. |

| Suitability for High-Speed Transmission | Ribbon cables support advanced network speeds, making them ideal for modern data center applications. |

By enabling efficient data transmission and reducing installation time, ribbon fiber optic cables enhance the overall performance of high-density data centers. Their ability to handle the growing demands of data-intensive applications ensures their continued relevance in the evolving telecom landscape.

Loose Tube Fiber Optic Cable

Features and Benefits

Loose Tube Fiber Optic Cable stands out as a robust solution for industrial telecom infrastructure, particularly in outdoor environments. Its unique construction allows the fiber core to move freely within protective tubes, accommodating temperature fluctuations and reducing the risk of damage. This design enhances durability, making it suitable for installations in harsh conditions.

The inclusion of water-resistant gel within the tubes provides additional protection against moisture, ensuring reliable performance in high-humidity areas. Loose tube cables also feature strength members that improve tensile strength, making them ideal for aerial installations. Their ability to withstand UV radiation, chemicals, and physical stress further underscores their suitability for challenging environments.

A high fiber count configuration enables these cables to support large-scale data transmission, meeting the demands of modern telecom networks. Additionally, their flexibility simplifies installation and reduces the risk of fiber damage during deployment. Loose tube cables offer cost-effectiveness due to their long service life and minimal maintenance requirements.

| Advantage | Description |

|---|---|

| Environmental Protection | Protects against moisture, UV radiation, temperature fluctuations, and physical stress. |

| Flexibility | Allows greater flexibility, simplifying installation and reducing fiber damage risk. |

| High Fiber Count | Supports high-capacity data transmission with configurations featuring numerous fibers. |

| Thermal Expansion Accommodation | Prevents damage by accommodating thermal expansion and contraction. |

| Tensile Strength | Enhances durability for aerial installations through reinforced strength members. |

| Repairability | Facilitates easier access and repair of damaged fibers without replacing the entire cable. |

| Harsh Environment Suitability | Performs reliably in extreme weather conditions, chemicals, and physical stress. |

| Longevity | Offers extended service life when properly installed and maintained. |

| Versatility | Suitable for applications ranging from long-haul telecommunications to underwater deployments. |

| Cost-Effectiveness | Reduces replacement and maintenance costs over time due to its durability. |

Applications in Outdoor and Underground Installations

Loose Tube Fiber Optic Cable excels in outdoor and underground installations, where environmental challenges demand robust solutions. Its ability to accommodate thermal expansion and contraction makes it ideal for areas with fluctuating temperatures. The water-resistant gel protects against moisture, ensuring reliable performance in underground deployments.

In tunnel monitoring, these cables enable strain and temperature measurements along tunnel linings, covering lengths of up to 220 meters. Their distributed sensing capabilities allow for continuous data collection across hundreds of points, eliminating blind spots. Unlike traditional methods requiring direct line of sight, fiber optic sensors embedded within structures provide uninterrupted data collection, even during construction activities.

| Application | Description |

|---|---|

| Monitoring Tunnel Linings | Enables strain and temperature monitoring along tunnel cross-sections, covering up to 220 meters. |

| Distributed Measurements | Facilitates continuous data collection across hundreds of sensing points without blind spots. |

| Overcoming Line of Sight Issues | Operates reliably without interference from construction activities, ensuring accurate data collection. |

Loose tube cables also perform well in outdoor installations, such as long-haul telecommunications and aerial deployments. Their tensile strength and environmental resistance make them indispensable for maintaining connectivity in challenging conditions. By offering durability, flexibility, and high data transmission capacity, Loose Tube Fiber Optic Cable remains a preferred choice for industrial telecom infrastructure.

Tight-Buffered Fiber Optic Cable

Features and Benefits

Tight-buffered fiber optic cables are engineered for versatility and durability, making them a preferred choice for indoor and campus network applications. Their construction includes 900 µm buffered fibers, which simplify stripping and ensure consistent performance during installation. The cables also feature 2.0 mm subunits, facilitating efficient field terminations and reducing installation time.

The flame-retardant jacket enhances ruggedness and durability, ensuring the cables can withstand challenging conditions. Additionally, their temperature- and water-resistant properties provide superior protection in environments prone to moisture or temperature fluctuations. The all-dielectric construction eliminates the need for grounding or bonding, further simplifying deployment.

| Feature | Benefit |

|---|---|

| Waterblocking technology | Suitable for outdoor applications |

| Small diameter and bend radius | Facilitates installation in tight spaces |

| Color-coded fibers | Enables quick identification |

| All-dielectric construction | Eliminates need for grounding or bonding |

| UV-resistant, flame-retardant jacket | Ensures durability and ease of stripping |

These cables also excel in environments requiring high flexibility. Their small diameter and bend radius allow for easy installation in confined spaces, while color-coded fibers enable quick identification during maintenance. Tight-buffered fiber optic cables provide a reliable and efficient solution for modern telecom infrastructure.

Applications in Indoor and Campus Networks

Tight-buffered fiber optic cables are widely used in indoor and campus networks due to their adaptability and performance. They serve as a backbone for intra-building connections, linking different parts of a structure to create a robust network infrastructure. These cables also facilitate communication between telecom rooms, ensuring seamless data transfer across various areas.

In data centers, tight-buffered cables support high-density connectivity and efficient data management. Their durability and flexibility make them ideal for structured cabling systems, where organized and reliable performance is critical. Additionally, they enable building-to-building connections, enhancing overall connectivity in campus environments.

| Application Type | Description |

|---|---|

| Intra-building backbones | Used to connect different parts of a building, providing a robust network infrastructure. |

| Connections between telecom rooms | Facilitates communication and data transfer between different telecommunications areas. |

| Data center applications | Supports high-density connectivity and efficient data management within data centers. |

| LANs (Local Area Networks) | Provides connectivity within localized areas such as offices and campuses. |

| Building-to-Building Connections | Enables networking between separate buildings, enhancing overall connectivity. |

| Structured Cabling | Organizes cabling systems for efficient management and performance in various environments. |

| Harsh Indoor Environments | Designed to withstand challenging indoor conditions while maintaining performance. |

These cables also perform well in harsh indoor environments, where their flame-retardant and water-resistant properties ensure consistent performance. By offering reliability, flexibility, and ease of installation, tight-buffered fiber optic cables remain a cornerstone of indoor and campus network infrastructure.

Aerial Fiber Optic Cable

Features and Benefits

Aerial fiber optic cables are specifically designed to deliver reliable performance in overhead installations. Their construction prioritizes strength, flexibility, and lightweight properties, making them suitable for various industrial telecom applications. These cables often feature protective materials like Kevlar and UV-resistant jackets, ensuring durability in outdoor environments.

- Design and Construction: Aerial cables are built to withstand environmental challenges, including UV exposure and mechanical stress.

- Types and Applications: All-Dielectric Self-Supporting (ADSS) cables are ideal for long spans without electrical support, while Optical Ground Wire (OPGW) cables combine data transmission with lightning protection.

- Installation and Maintenance: These cables can be installed using existing utility poles, reducing the need for excavation and lowering installation costs.

- Performance and Reliability: They provide high bandwidth, low latency, and resistance to electromagnetic interference, ensuring seamless data transmission.

- Cost Considerations: Aerial installations are cost-effective due to reduced excavation requirements and the ability to leverage existing infrastructure.

The combination of these features makes aerial fiber optic cables a preferred choice for high-data-rate applications in industrial telecom infrastructure.

Applications in Overhead Installations

Aerial fiber optic cables excel in overhead installations, where they utilize existing utility poles to minimize disruption and costs. Their ability to maintain performance in challenging conditions makes them indispensable for industrial and urban networks. Proper installation and maintenance guidelines ensure their reliability and longevity.

| Guideline Number | Description |

|---|---|

| 40 | Reel vault locations should be near sharp bends, and pulling locations should be at corner vaults. |

| 58 | Extreme caution is necessary near high-voltage lines, with proper personnel present on-site. |

| 59 | All cables near high-voltage power lines, including all-dielectric cables, should be grounded. |

| 60 | Maintain clearance between fiber optic and power cables, accounting for sag due to weather or current. |

| 61 | Avoid zigzagging steel messenger wires; keep them on one side of the pole for stability. |

These guidelines highlight the importance of safety and precision during aerial installations. By adhering to these practices, organizations can ensure the optimal performance of their fiber optic cable networks. Aerial cables remain a cost-effective and efficient solution for expanding telecom infrastructure, particularly in areas where underground installations are impractical.

Underwater Fiber Optic Cable

Features and Benefits

Underwater fiber optic cables are critical for establishing reliable communication networks across oceans and coastal regions. These cables offer several advanced features that make them indispensable for submarine telecom infrastructure:

- Exceptional Signal Clarity: The optical fibers used in these cables allow data transmission over distances exceeding 100 kilometers between repeaters, ensuring minimal signal degradation.

- Cost-Effectiveness: Unrepeated cables reduce installation costs while supporting longer transmission distances, making them an economical choice for large-scale projects.

- Redundancy and Reliability: Modern systems incorporate self-healing ring configurations, ensuring uninterrupted service even during cable faults.

- Advanced Sensing Capabilities: Optical-based sensing technology provides larger bandwidth, faster speeds, and lower latency compared to traditional acoustic systems.

- Real-Time Monitoring: Distributed fiber-optic sensors enable continuous monitoring, transforming these cables into extensive underwater sensor networks.

These features not only enhance data transmission efficiency but also contribute to the development of robust and sustainable global communication systems.

Applications in Submarine and Coastal Networks

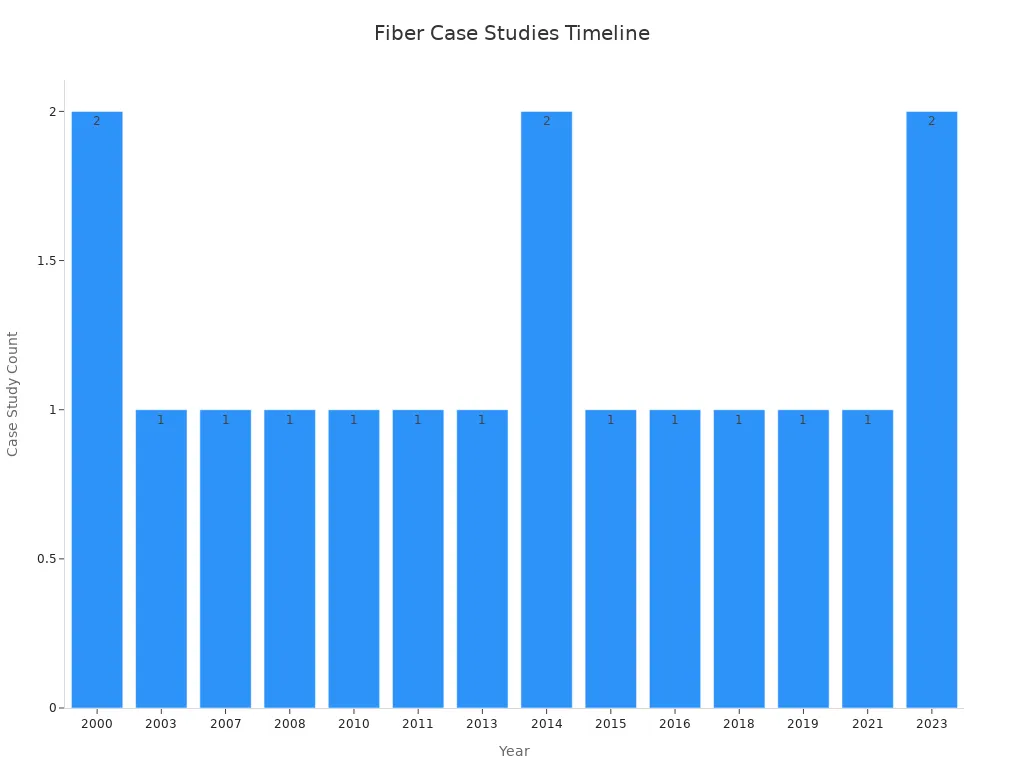

Underwater fiber optic cables play a pivotal role in connecting continents, islands, and coastal regions. Their applications extend beyond traditional telecom networks, addressing diverse needs in environmental monitoring and energy systems. The following table highlights notable case studies of submarine cable installations:

| Project Name | Year | Summary |

|---|---|---|

| Pioneer Seamount | 2003 | Explored environmental impacts of cable movement and interactions with marine life. |

| Tuen Mun | 2000 | Found negligible environmental impacts from cable installation in Hong Kong. |

| Southeast Asia – Japan 2 Cable System (SJC2) | 2023 | Concluded no significant adverse effects from submarine cable construction in Singapore. |

| Fundy Isles Submarine Cables Replacement | 2018 | Identified short-term sediment disturbance during cable installation. |

| Tanzania | 2010 | Assessed moderate impacts from a 2,000 km subsea cable, with mitigation measures applied. |

These cables also support environmental monitoring by enabling strain and temperature measurements along ocean floors. For example, distributed fiber-optic sensors embedded in submarine cables provide real-time data on seismic activity and ocean currents. This capability enhances disaster preparedness and marine ecosystem management.

Underwater fiber optic cables remain a cornerstone of global connectivity. Their ability to transmit vast amounts of data efficiently and reliably ensures their continued relevance in modern telecom infrastructure.

Specialty Fiber Optic Cable for Extreme Conditions

Features and Benefits

Specialty fiber optic cables are engineered to perform reliably in the most challenging environments. These cables incorporate advanced materials and innovative designs to withstand extreme temperatures, corrosive chemicals, and high-pressure conditions. For instance, the VHM5000 Series fibers feature hermetic coatings that protect against hydrogen-induced loss, ensuring durability in downhole applications within the oil and gas industry. Proprietary glass chemistry further enhances resistance to hydrogen and water, maintaining signal integrity even after prolonged exposure to harsh conditions.

Recent advancements in carbon coating technology have significantly improved the performance of these cables. The carbon layer acts as a robust barrier against hydrogen diffusion, ensuring the fibers remain functional under high temperatures. Additionally, the VHS400 range of silica core double-wavelength single-mode optical fibers demonstrates enhanced performance at 1550 nm and 1310 nm wavelengths, making them ideal for critical applications in extreme conditions.

The demand for specialty fiber optic cables continues to grow, driven by their enhanced security and reliability. These cables are essential for sectors like IoT, cloud computing, and disaster recovery, where uninterrupted connectivity is crucial. Furthermore, their ability to endure harsh environmental factors, such as UV radiation and moisture, makes them indispensable for telecommunications and FTTH networks.

Applications in High-Temperature or Corrosive Environments

Specialty fiber optic cables excel in environments where standard cables fail. Their high glass transition temperature and NASA low outgassing approval make them suitable for high-temperature applications, such as industrial furnaces and aerospace systems. These cables also demonstrate exceptional durability in corrosive environments, including chemical plants and offshore oil rigs.

The following table highlights key performance features of these cables in extreme conditions:

| Feature | Description |

|---|---|

| Long pot life | Ensures extended usability before curing |

| High glass transition temperature | Suitable for high-temperature applications |

| NASA low outgassing approved | Safe for sensitive environments |

| Low shrinkage | Maintains integrity during curing |

| Superior optical transmission | Essential for effective signal transfer |

| 1,000 hours at 85°C/85% humidity | Demonstrates durability in humid conditions |

| Dual Cure systems | Versatile curing options available |

| Environmentally friendly | Solvent-free options available |

These cables also play a vital role in sensing applications. Distributed fiber-optic sensors embedded in these cables provide real-time monitoring of temperature and strain in high-risk environments. This capability enhances safety and operational efficiency in industries like energy, manufacturing, and transportation. By combining durability, reliability, and advanced sensing capabilities, specialty fiber optic cables remain a cornerstone of modern industrial telecom infrastructure.

Dowell Fiber Optic Cable Solutions

Overview of Dowell’s Innovative Product Range

Dowell Fiber Optic Cable Solutions have revolutionized industrial telecom infrastructure by offering products that combine durability, efficiency, and advanced technology. These solutions are designed to perform in challenging environments, ensuring seamless data transmission and operational reliability. Dowell’s product range includes armored cables for harsh conditions, underwater cables for submarine networks, and specialty cables for extreme environments. Each product is meticulously engineered to meet the diverse needs of modern industries.

Dowell plays a crucial role in strengthening global telecom infrastructure. The brand’s solutions facilitate efficient fiber deployment, even in challenging conditions.

The integration of Dowell’s solutions enhances productivity and operational efficiency. Their role in enabling smart manufacturing and predictive maintenance highlights their importance in industrial applications. Key features of Dowell’s products include:

| Feature | Description |

|---|---|

| Durability | Armored design protects against physical damage, ideal for harsh environments. |

| Signal Loss | High-quality construction minimizes signal loss for uninterrupted data transmission. |

| Application | Suitable for industrial settings and underground installations. |

Dowell’s innovative approach ensures their products remain at the forefront of the fiber optic cable industry, addressing the growing demands of industrial telecom networks.

Why Dowell is a Trusted Leader in Industrial Telecom

Dowell has established itself as a trusted leader in the fiber optic cable industry through its commitment to quality, innovation, and customer satisfaction. The company invests heavily in research and development, ensuring its products incorporate cutting-edge technology. Each product undergoes rigorous testing to guarantee durability and reliability, fostering trust among its global clientele.

- Cutting-Edge Technology: Dowell consistently innovates to stay ahead in the industry.

- High-Quality Products: Rigorous testing ensures every product meets the highest standards.

- Customized Solutions: Tailored offerings address unique customer requirements.

- Timely Response: Round-the-clock customer support ensures prompt assistance.

- Global Reach: Dowell’s products are trusted worldwide, reflecting their ability to serve diverse markets.

Dowell’s ability to deliver tailored solutions further enhances its reputation. By addressing specific customer needs, the company ensures satisfaction and long-term partnerships. Its global reach and reliable customer support solidify its position as a leader in industrial telecom infrastructure.

The top 10 fiber optic cable solutions outlined in this blog demonstrate their critical role in shaping industrial telecom infrastructure in 2025. Each solution addresses specific challenges, from long-distance communication to extreme environmental conditions, ensuring robust and efficient networks. The fiber optic cable market is projected to grow significantly, reaching USD 43.99 billion by 2032, driven by advancements in 5G, IoT, and cloud computing technologies. Selecting the right cable type is essential for optimizing performance and minimizing costs, as highlighted by surveys and consumer insights from industry experts and network operators.

Dowell continues to lead the industry with innovative and reliable fiber optic cable solutions. Their commitment to quality and advanced technology ensures seamless connectivity, even in the most demanding environments. By addressing diverse industrial needs, Dowell remains a trusted partner in building the telecom infrastructure of the future.

FAQ

What is the difference between single-mode and multi-mode fiber optic cables?

Single-mode cables transmit data over long distances with minimal signal loss, making them ideal for telecommunications. Multi-mode cables, on the other hand, are cost-effective and suitable for short-distance applications like campus networks due to their larger core diameter and simplified installation process.

How do armored fiber optic cables protect against environmental damage?

Armored cables feature protective layers, such as steel tubes and Kevlar, which shield against physical stress, moisture, and rodent attacks. These layers ensure durability and reliable performance in harsh industrial environments, including underground and outdoor installations.

Why are ribbon fiber optic cables preferred in high-density data centers?

Ribbon cables offer high fiber density in a compact design, saving space in data centers. Their pre-banded fibers enable faster splicing and installation, reducing labor costs and downtime. These features make them ideal for environments requiring efficient, high-speed connectivity.

Can underwater fiber optic cables monitor environmental conditions?

Yes, underwater cables equipped with distributed fiber-optic sensors can monitor seismic activity, ocean currents, and temperature changes. This capability supports disaster preparedness and marine ecosystem management, making them valuable for both telecom and environmental applications.

What makes Dowell a trusted provider of fiber optic cable solutions?

Dowell combines advanced technology, rigorous testing, and tailored solutions to meet diverse industrial needs. Their products ensure durability, reliability, and seamless connectivity in challenging environments, solidifying their reputation as a leader in the fiber optic cable industry.

Post time: Apr-17-2025