What Are Horizontal Fiber Optic Splice Closures?

Horizontal fiber optic splice closures serve a crucial role in the telecommunications industry. They provide a secure environment for splicing fiber optic cables, ensuring the integrity of connections. These closures offer protection against environmental factors, such as water and dust, due to their robust design. Typically made from high tensile construction plastic, they withstand extreme temperatures ranging from -40°C to 85°C. Their design accommodates hundreds of fiber connections, making them ideal for backbone network applications. By offering a reliable solution for fiber splicing, horizontal fiber optic splice closures enhance network performance and longevity.

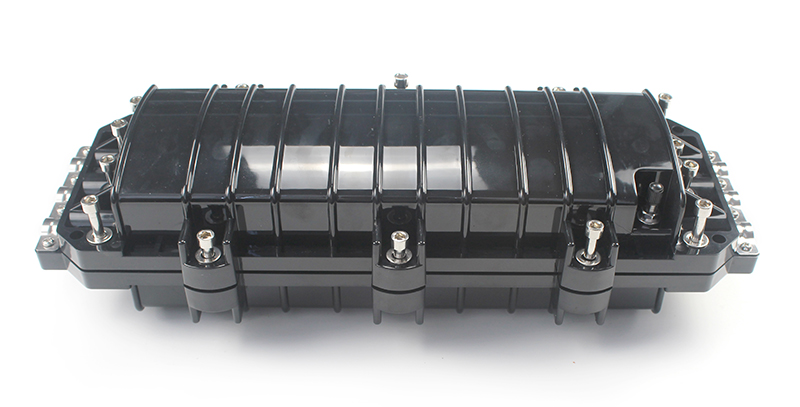

Characteristics of Horizontal Fiber Optic Splice Closures

Design Features

Horizontal configuration

Horizontal fiber optic splice closures exhibit a unique design that resembles a flat or cylindrical box. This configuration allows them to efficiently house and protect fiber optic cable splices. Their horizontal layout makes them suitable for various installation environments, including aerial, buried, and underground applications. The design ensures that the closures can accommodate a large number of fiber connections, making them ideal for complex network setups.

Material and durability

Manufacturers construct horizontal fiber optic splice closures using high-strength materials, such as durable plastics or metals. These materials provide robust protection against environmental challenges like moisture, dust, and temperature fluctuations. The closures can withstand extreme temperatures ranging from -40°C to 85°C, ensuring reliable performance in diverse conditions. Their weather-resistant properties make them a preferred choice for outdoor and underground installations.

Functionality

Protection of fiber splices

Horizontal fiber optic splice closures play a vital role in safeguarding fiber splices from environmental and mechanical damage. They create a secure enclosure that maintains the integrity of the fiber connections. The closures feature sealing mechanisms, either mechanical or heat-shrink, to ensure they remain water and dust-proof. This protection is crucial for maintaining uninterrupted service and optimal network performance.

Capacity and scalability

These closures offer significant capacity and scalability, accommodating hundreds of fiber connections within a single unit. They come equipped with multiple in/out ports and drop ports, allowing for flexible network expansion. The design supports various configurations, making it easy to scale up as network demands grow. This adaptability makes horizontal fiber optic splice closures a cost-effective solution for expanding telecommunications infrastructure.

Installation Options for Horizontal Fiber Optic Splice Closures

Indoor vs. Outdoor Installation

Environmental considerations

When installing horizontal fiber optic splice closures, environmental factors play a crucial role. Indoor installations typically face fewer environmental challenges. However, outdoor installations must withstand harsh conditions. These include exposure to moisture, temperature fluctuations, and UV radiation. The robust design of these closures ensures they can endure such conditions. They protect the fiber splices from potential damage, maintaining network integrity.

Mounting techniques

Mounting techniques vary based on the installation environment. Indoor installations often use wall-mounted brackets. These provide easy access for maintenance. Outdoor installations require more durable solutions. Technicians may use pole mounts or underground vaults. These methods ensure the closures remain secure and protected from external elements. Proper mounting is essential for the longevity and reliability of the fiber optic network.

Installation Process

Tools and equipment needed

Installing a horizontal fiber optic splice closure requires specific tools and equipment. Technicians need fiber optic splicing tools, such as cleavers and fusion splicers. They also require sealing materials, like heat-shrink tubes or mechanical seals. Additionally, mounting brackets and screws are necessary for securing the closure. Having the right tools ensures a smooth installation process.

Step-by-step guide

- Preparation: Gather all necessary tools and materials. Ensure the work area is clean and organized.

- Cable Preparation: Strip the outer jacket of the fiber optic cable. Clean the fibers to remove any debris.

- Splicing: Use a fusion splicer to join the fiber ends. Ensure the splices are secure and free from defects.

- Sealing: Place the spliced fibers inside the closure. Use sealing materials to protect against moisture and dust.

- Mounting: Secure the closure using appropriate mounting techniques. Ensure it is stable and accessible for future maintenance.

- Testing: Perform tests to verify the integrity of the splices. Ensure the network operates efficiently.

“Consider how easy it is to install and if it allows re-entry for future maintenance,” advises a Technician deploying fiber optic for Swisscom. This insight highlights the importance of choosing closures that facilitate both initial installation and future access.

Applications of Horizontal Fiber Optic Splice Closures

Telecommunications

Use in network expansions

Horizontal fiber optic splice closures play a pivotal role in telecommunications, especially during network expansions. As the demand for faster and more reliable internet grows, service providers need to expand their networks efficiently. These closures allow technicians to splice multiple fibers together, creating a seamless connection that supports increased data traffic. By accommodating numerous fiber connections, they enable the expansion of existing networks without compromising performance. This capability is crucial in urban areas where space is limited, and network density is high.

Role in data centers

Data centers rely heavily on horizontal fiber optic splice closures to maintain robust and efficient communication networks. These closures ensure that data centers can handle large volumes of data transmission with minimal signal loss. By protecting fiber splices from environmental and mechanical damage, they help maintain the integrity of data connections. This reliability is essential for data centers, which require uninterrupted service to support critical operations. The scalability of these closures also allows data centers to expand their infrastructure as data demands increase.

Other Industries

Utility companies

Utility companies benefit from the use of horizontal fiber optic splice closures in their communication networks. These closures provide a secure environment for fiber splicing, ensuring reliable data transmission across vast distances. Utility companies use them to monitor and control their infrastructure, such as power grids and water systems. By maintaining the integrity of fiber connections, these closures help utility companies deliver consistent and efficient services to their customers.

Military and defense

The military and defense sectors utilize horizontal fiber optic splice closures to enhance their communication networks. These closures offer robust protection for fiber splices, ensuring secure and reliable data transmission in challenging environments. Military operations often require rapid deployment and adaptability, making the scalability of these closures an asset. By supporting complex communication networks, they enable military and defense organizations to maintain operational efficiency and security.

Comparing Horizontal and Other Types of Fiber Optic Splice Closures

Horizontal vs. Vertical Closures

Design differences

Horizontal and vertical fiber optic splice closures differ significantly in design. Horizontal closures resemble flat or cylindrical boxes, providing ample space for in-line splicing. This design allows them to accommodate hundreds of fiber connections, making them ideal for complex network setups. They are typically elongated, which facilitates efficient installation in various environments, including outdoor and underground settings. In contrast, vertical closures are often used for branching applications. Their design supports aerial, buried, or underground installations, where branching of fiber lines is necessary.

Use case scenarios

Horizontal closures find widespread use in scenarios requiring robust protection and high capacity. They are commonly employed in outdoor or underground installations, where environmental factors like moisture and dust pose significant challenges. Their waterproof and dustproof features ensure reliable performance in harsh conditions. Vertical closures, on the other hand, are more suited for applications involving branching of fiber lines. They are often used in aerial installations, where space constraints and the need for branching connections dictate their use.

Why Choose Horizontal Closures?

Advantages over other types

Horizontal fiber optic splice closures offer several advantages over other types. Their design provides a secure environment for splicing, ensuring the integrity of fiber connections. They support a large number of fiber splices, making them suitable for expanding networks. The closures’ robust construction protects against environmental damage, maintaining network performance and longevity. Additionally, their versatility allows for use in various installation environments, from indoor setups to challenging outdoor conditions.

Cost-effectiveness

Choosing horizontal closures can be a cost-effective solution for many network applications. Their ability to accommodate numerous fiber connections within a single unit reduces the need for multiple closures, saving on installation and maintenance costs. The scalability of these closures allows for easy network expansion without significant additional investment. By providing reliable protection and supporting network growth, horizontal closures offer a practical and economical choice for telecommunications and other industries.

Selecting the right fiber optic splice closure is vital for network performance and longevity. Horizontal closures offer significant advantages, including robust protection and scalability. They are more commonly used than vertical closures due to their ability to extend fiber connections seamlessly. These closures save time and space while providing reliable protection. When choosing a closure type, individuals should consider environmental conditions, accessibility, and future expansion needs. By aligning the choice with specific requirements, users can ensure optimal network functionality and durability.

Post time: Dec-02-2024