Fiber Optic Distribution Boxes play a vital role in FTTx networks by ensuring efficient and reliable connectivity. The 16F Fiber Optic Distribution Box, in particular, provides robust protection with IP55-rated weather resistance, making it suitable for extreme conditions. These Fiber Optic Boxes centralize fiber connections, improving data transmission efficiency and reducing signal loss. Their scalability also supports future network expansions while optimizing space and costs.

Key Takeaways

- Fiber Optic Distribution Boxes improve networks by organizing connections and reducing mess.

- They shield fiber optic cables from weather, making networks last longer and stay reliable.

- Buying a flexible Fiber Optic Distribution Box helps your network grow and saves money.

Importance of Fiber Optic Distribution Boxes in FTTx Networks

Enhancing Network Efficiency and Reliability

A Fiber Optic Distribution Box plays a critical role in improving the efficiency and reliability of FTTx networks. By centralizing fiber connections, it allows you to manage multiple cables more effectively. This organization reduces clutter and simplifies maintenance tasks, saving time and effort. Additionally, the streamlined infrastructure minimizes the risk of cable damage, ensuring consistent performance.

You also benefit from enhanced data security. Fiber optics are immune to electromagnetic interference and difficult to tap without physical access, making them a secure choice for modern networks. Moreover, the box’s design prevents excessive bending or tangling of cables, reducing signal loss and improving transmission quality. This results in faster network speeds and better responsiveness, which are essential for high-density environments.

Protecting Fiber Optic Cables from Environmental Factors

Environmental factors like moisture, dirt, and temperature fluctuations can severely impact fiber optic cables. A Fiber Optic Distribution Box shields your cables from these threats, extending the lifespan of your network. For example, its weather-resistant materials and sealing mechanisms protect against moisture and contaminants.

In outdoor installations, the box provides mechanical protection against impacts and vibrations. This durability ensures stable connectivity even in harsh conditions. Whether in residential or industrial settings, the robust construction of these boxes simplifies maintenance and safeguards your network from environmental challenges.

| Environmental Factor | Mitigation Strategy |

|---|---|

| Temperature Variations | Use weather-resistant materials |

| Moisture | Seal the distribution box |

| Physical Damage | Provide mechanical protection |

Supporting Scalability and Future Network Growth

As your network grows, scalability becomes a priority. A Fiber Optic Distribution Box supports this need with its modular design, allowing you to add, remove, or reroute connections easily. This adaptability is crucial in high-density environments where service disruptions must be minimized.

The box also facilitates fiber optic splicing and minimizes signal loss, ensuring high-quality data transmission. Its future-proof design makes it a cost-effective solution for expanding networks. By investing in a reliable distribution box, you prepare your network for future demands while maintaining optimal performance.

Types of Fiber Optic Distribution Boxes

Based on Connection Type

Fiber optic distribution boxes vary based on the type of connections they support. Some boxes are designed for splicing, where you can join two fiber optic cables permanently. Others focus on patching, allowing you to connect and disconnect cables easily using adapters. These options give you flexibility in managing your network. For example, splicing boxes are ideal for long-term installations, while patching boxes work well in environments requiring frequent changes.

Additionally, some boxes combine both splicing and patching capabilities. This hybrid design simplifies network management by offering a single solution for multiple tasks. Whether you need to splice cables or connect them temporarily, you can find a box tailored to your needs.

Based on Port Number and Capacity

The capacity of a fiber optic distribution box depends on the number of ports it offers. Boxes can range from small models with 4 or 6 ports to larger ones with 24 or more. Choosing the right capacity ensures your network can handle current demands while leaving room for future growth. For instance, a 16-port box like the 16F Fiber Optic Distribution Box is perfect for medium-sized networks, offering a balance between scalability and cost.

| Type of Box | Typical Ports | Use Environment |

|---|---|---|

| Fiber Optical Termination Box | 12, 24, 48 ports | Indoor (data centers) |

| Fiber Optic Distribution Box | 4, 6, 8, 12, 16, 24, 48 | Outdoor, indoor, corridor |

| Optical Distribution Frame (ODF) | 12 to 144 ports | Equipment rooms |

Based on Material and Durability

The materials used in a fiber optic distribution box significantly impact its durability. Common materials include ABS+PC, SMC, and PP. ABS+PC is cost-effective and meets most requirements, while SMC offers premium quality at a higher price. High-grade polycarbonate and ABS plastic provide excellent impact resistance and longevity, ensuring your box withstands mechanical stress and environmental exposure.

When selecting a box, consider the installation environment. For outdoor use, prioritize materials that resist weather conditions. Indoor installations can use lighter materials, as they face fewer environmental challenges.

Indoor vs. Outdoor Applications

Indoor and outdoor fiber optic distribution boxes serve different purposes. Indoor boxes often feature compact, space-saving designs, making them ideal for confined spaces like data centers. Outdoor boxes, on the other hand, offer enhanced durability and weather resistance. They protect cables from moisture, temperature fluctuations, and physical damage.

- Flexible Installation: Both types allow easy customization for various setups.

- Connector Compatibility: Supports a wide range of fiber connectors.

- Durability and Protection: Outdoor boxes withstand extreme conditions, while indoor boxes focus on efficient space use.

By understanding these differences, you can choose the right box for your specific application.

Key Functions of Fiber Optic Distribution Boxes

Fixing and Securing Fiber Optic Cables

A Fiber Optic Distribution Box ensures that your cables remain secure and organized. Its robust design protects fibers from moisture, dirt, and contaminants, which helps extend the lifespan of your network. The sturdy construction also shields cables from physical damage caused by impacts or vibrations, ensuring stable connections and reducing signal loss.

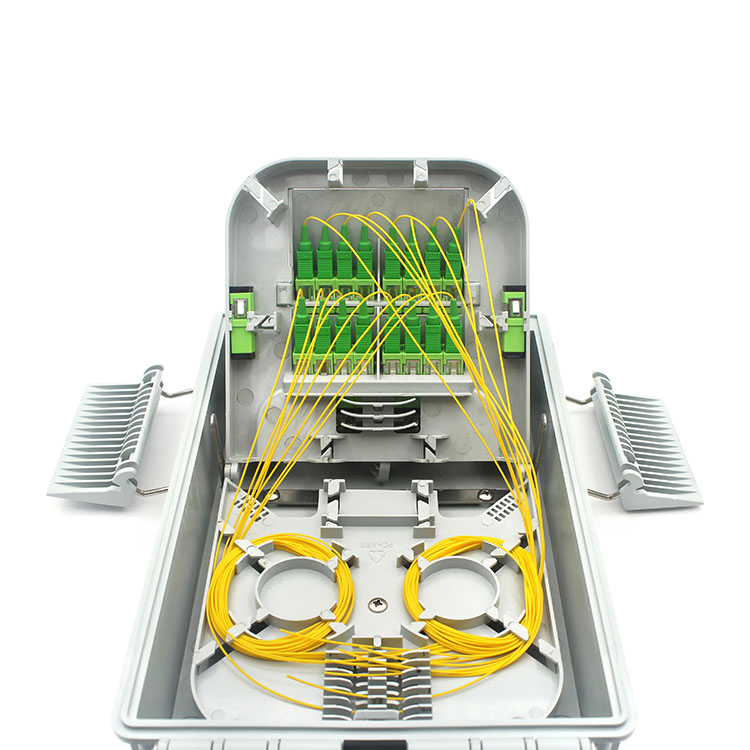

Inside the box, the layout keeps cables neatly arranged, minimizing clutter and making it easier for you to identify specific cables during maintenance. This organization reduces the risk of tangling or damage, ensuring smooth data transmission. Additionally, the box provides a controlled environment for splicing, holding fibers securely to prevent movement or breakage.

Splicing and Terminating Fiber Connections

Splicing and terminating fiber connections require precision and proper tools. A distribution box simplifies this process by offering a dedicated space for these tasks. You can use fast connectors to terminate cables quickly, enhancing network performance and reliability. Always label each cable for easy identification during troubleshooting.

To ensure optimal results, follow best practices like choosing compatible connectors and testing fibers for loss after installation. Adequate space for termination and the use of service loops further improve efficiency. In dusty environments, clean tools and connectors frequently to avoid contamination. These steps help maintain the integrity of your fiber optic connections.

Deploying and Distributing Fiber Optic Lines

Fiber Optic Distribution Boxes play a crucial role in deploying and distributing fiber optic lines. They protect cables from environmental factors like moisture and dirt, which extends the network’s lifespan. The internal design organizes fibers neatly, reducing clutter and minimizing the risk of damage.

These boxes also provide a controlled environment for splicing and termination, which enhances network reliability. Their user-friendly design allows for easy access, simplifying maintenance and repairs. This ensures continuous network performance, even in demanding conditions.

Storing and Protecting Excess Fiber

Excess fiber can pose challenges if not managed properly. A distribution box offers a practical solution by providing storage space for unused fiber. This prevents tangling and damage, keeping your network organized and efficient.

The box’s durable construction protects stored fibers from environmental hazards and physical impacts. By safely housing excess fiber, you can maintain a clean and functional setup, which simplifies future upgrades or repairs.

How to Install a Fiber Optic Distribution Box

Preparing the Installation Site

Proper site preparation ensures the long-term reliability of your fiber optic distribution box. Start by choosing a location that is easy to access for maintenance and upgrades. Protect the box from environmental elements like moisture and extreme temperatures. Place it close to connected equipment to minimize cable length and signal loss.

Tip: Ensure proper ventilation to prevent overheating and avoid cramped areas that could obstruct access during inspections or repairs.

Consider key factors such as accessibility, cable routing, and safety requirements. Dowell’s fiber optic distribution boxes are designed to fit seamlessly into various environments, making site preparation straightforward and efficient.

Mounting the Distribution Box

Mounting the box securely is critical for stable performance. Gather essential tools like a screwdriver set, cable stripping tools, and fiber optic cleaning supplies. Use a fiber optic splicing machine and fusion splicer for precise fiber alignment.

Follow these steps:

- Select an appropriate location based on accessibility and environmental conditions.

- Securely mount the box using the manufacturer’s guidelines and appropriate hardware.

- Ensure the box is level and firmly attached to prevent vibrations or movement.

Dowell’s distribution boxes feature durable materials that simplify mounting, whether indoors or outdoors.

Connecting and Organizing Fiber Cables

Organizing cables during installation prevents future issues. Label each cable for easy identification and bundle them neatly to avoid tangling. Use protective conduits to shield cables from damage.

Best Practices:

- Avoid twisting cables to prevent stress on fibers.

- Roll cables off the spool to maintain their integrity.

- Use hand-tightened cable ties to avoid crushing the fibers.

Dowell’s fiber optic distribution boxes provide ample space for clean cable management, ensuring a streamlined setup.

Testing and Finalizing the Installation

Testing verifies the integrity of your installation. Perform a visual inspection using a fiber optic microscope to check for imperfections. Measure signal loss with a power meter and use an Optical Time-Domain Reflectometer (OTDR) to identify splice or connection issues.

| Test Type | Tool Required | Purpose |

|---|---|---|

| Visual Inspection | Fiber Optic Microscope | Check for imperfections |

| Signal Loss | Power Meter | Measure light transmission |

| Reflectance | Optical Time-Domain Reflectometer | Identify splice/connection issues |

Conduct end-to-end insertion loss testing to ensure total loss remains below the calculated maximum. Dowell’s fiber optic distribution boxes are engineered for easy testing and maintenance, making them a reliable choice for your network.

Maintenance Tips for Fiber Optic Distribution Boxes

Regular Cleaning and Inspection

Regular cleaning and inspection keep your Fiber Optic Distribution Box in optimal condition. Dust and debris can accumulate over time, potentially affecting performance. Use a soft, lint-free cloth to clean the exterior and a fiber optic cleaning kit for internal components. Inspect the box for any irregularities during cleaning.

Pay attention to the following:

- Check for loose or disconnected cables.

- Look for signs of wear, such as frayed wires or damaged connectors.

- Ensure all ports and seals remain intact.

By addressing these issues early, you can prevent costly repairs and maintain network reliability.

Monitoring for Physical Damage and Wear

Physical damage can compromise the performance of your Fiber Optic Distribution Box. Regularly inspect the box to identify potential problems. Common signs of damage include:

- Loose connections.

- Cracks or dents on the box surface.

- Visible wear on cables or connectors.

If you notice any of these issues, take immediate action to repair or replace the affected components. Dowell’s distribution boxes are designed for durability, but proactive monitoring ensures long-term performance.

Ensuring Proper Sealing Against Environmental Factors

Proper sealing protects your Fiber Optic Distribution Box from environmental hazards like moisture, dust, and extreme temperatures. Advanced sealing technologies enhance durability and reliability.

| Sealing Technology | Benefits |

|---|---|

| Heat-shrink systems | Protects against moisture and dust |

| Gel-based systems | Enhances protection from extreme temperatures |

| Sturdy materials | Ensures durability against harsh weather |

| High IP ratings (IP68) | Provides complete protection against dust and water, including immersion in water for long durations. |

Choose a box with high-quality sealing, such as Dowell’s IP55-rated models, to safeguard your network in challenging environments.

Upgrading Components for Optimal Performance

Upgrading components ensures your Fiber Optic Distribution Box meets evolving network demands. Replace outdated connectors with high-performance alternatives to improve data transmission. Consider adding splitters or adapters to enhance capacity.

Tip: Schedule periodic upgrades to align with technological advancements and maintain peak efficiency.

Dowell’s distribution boxes offer modular designs, making upgrades simple and cost-effective. By staying proactive, you can future-proof your network and ensure uninterrupted service.

Fiber optic distribution boxes are vital for managing and distributing cables in FTTx networks. They enhance data transmission, simplify maintenance, and support scalability. Investing in a high-quality Fiber Optic Distribution Box, like the 16F model, ensures stable connections, protects fibers from damage, and prepares your network for future growth while optimizing performance and cost.

FAQ

What is the purpose of a Fiber Optic Distribution Box?

A Fiber Optic Distribution Box organizes, protects, and distributes fiber optic cables. It ensures efficient connectivity, safeguards cables from damage, and simplifies maintenance tasks in FTTx networks.

How do you choose the right Fiber Optic Distribution Box?

Consider capacity, material, and installation environment. For example, Dowell’s 16F Fiber Optic Distribution Box offers durability, scalability, and weather resistance, making it ideal for various applications.

Can a Fiber Optic Distribution Box be used outdoors?

Yes, outdoor models like Dowell’s IP55-rated Fiber Optic Distribution Box provide excellent protection against moisture, dust, and temperature changes, ensuring reliable performance in harsh environments.

Post time: Mar-07-2025