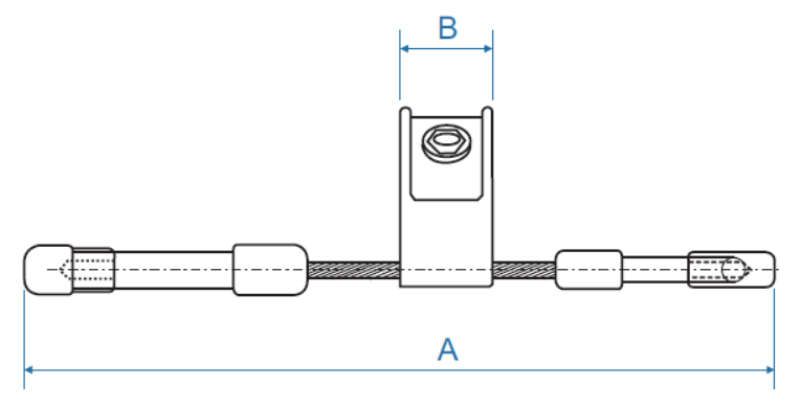

Stockbridge Vibration Damper

When the wire is subjected to wind, it will vibrate. When the wire vibrates, the working conditions of the wire suspension are the most unfavorable. Due to multiple vibrations, the wire will undergo fatigue damage due to periodic bending.

When the span of the overhead line is greater than 120 meters, a shock-proof hammer is generally used to prevent shock.

A main body which is formed from an elastic material into a substantially cubic overall form having a plurality of grooves, which grooves are connected with each other on one surface of the main body.

Features

1.Tuning fork structure: The anti-vibration hammer adopts a special tuning fork structure, which can generate four resonant frequencies, which greatly covers the vibration frequency range of the cable in reality.

2.Real materials: The hammer head is gray cast iron, painted. Anti-oxidation, corrosion resistance and long service life.

3.Various types of anti-vibration hammers: You can choose freely according to your needs.